What if a single misplaced molecule could halt the progress of a life-saving drug? In the fast-evolving world of biopharmaceuticals, oligonucleotide therapeutics stand at the forefront, offering hope for untreatable genetic disorders and rare diseases with their ability to target conditions at the

Imagine a world where life-saving biologics are produced faster, more efficiently, and at a scale never seen before, directly impacting millions of lives across the globe with groundbreaking advancements. This vision is becoming reality in Europe, where the biotech sector is witnessing a

Imagine a world where life-altering treatments for devastating conditions like glioblastoma or ovarian cancer are not just a scientific breakthrough but are accessible to every patient in need, regardless of location or financial means. This vision, though tantalizingly close in 2025, remains out

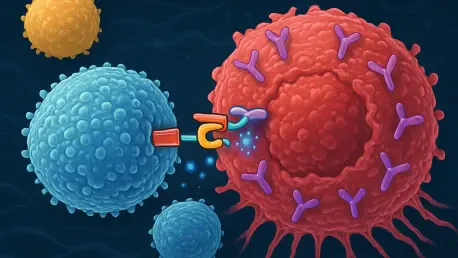

In the rapidly evolving landscape of cancer treatment, few innovations have captured as much attention as chimeric antigen receptor T cell (CAR-T) therapy, a groundbreaking method that reprograms a patient’s immune cells to attack cancer with remarkable precision. Originally developed as a niche

Introduction Imagine a world where life-saving cancer treatments, once out of reach due to exorbitant costs and lengthy production times, become accessible to patients in desperate need through groundbreaking innovations. CAR-T therapy, a revolutionary immunotherapy that modifies a patient's T

I'm thrilled to sit down with Ivan Kairatov, a renowned expert in biopharma with a wealth of experience in research and development, particularly in the rapidly evolving field of cell and gene therapies (CGTs). With his deep knowledge of technology and innovation in the industry, Ivan offers unique