I’m thrilled to sit down with Ivan Kairatov, a renowned biopharma expert with extensive experience in technology, innovation, and research and development within the industry. Today, we’re diving into the exciting world of biomanufacturing, focusing on a groundbreaking new lab at a prominent university in Kansas. Our conversation explores the lab’s purpose, its impact on student training, its role in addressing industry needs, and how it positions Kansas as a leader in this vital field. Let’s get started!

Can you walk us through the vision behind the new biomanufacturing lab at this Kansas university?

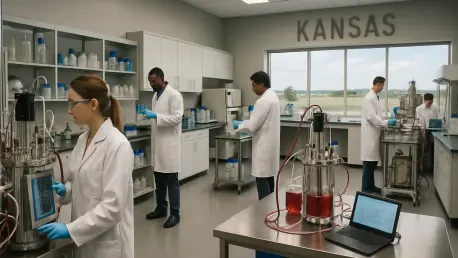

Absolutely. This lab, recently opened in Seaton Hall, is all about preparing the next generation of talent for the biopharma industry. Its core purpose is to serve as a cutting-edge training hub where students can master the latest techniques and technologies they’ll encounter in professional settings. It aligns perfectly with the university’s mission to bridge academic learning with real-world application, ensuring students are job-ready from day one.

What sets this facility apart from other training labs in the field?

What makes this lab stand out is its state-of-the-art design. It’s been described as a shiny, clean, and beautiful space that mirrors the environments students will work in at major companies like Pfizer or Merck. It’s not just about equipment; it’s about creating an immersive experience that replicates industry standards, giving students a true competitive edge through hands-on learning with the most advanced tools available.

How does this lab prepare students for their future careers?

The lab focuses on teaching critical skills in biomanufacturing, from operating sophisticated equipment to understanding complex processes like biologics production. These are exactly the skills that top employers are looking for. By training in an environment that mimics real-world facilities, students gain confidence and expertise, making them highly desirable candidates for roles in pharmaceuticals and beyond.

Why is biomanufacturing such a significant industry for Kansas in particular?

Kansas is actually a global leader in biomanufacturing, especially in animal health and pharmaceuticals. Industry experts have highlighted that the state is a powerhouse in these areas, with a rapidly growing sector that touches both human and animal health sciences. This lab strengthens that position by producing skilled professionals who can drive innovation and growth right here in the region, supporting a vital part of the state’s economy.

How does this new facility connect to the broader demand for skilled workers in the industry?

There’s an accelerating need for a talented workforce in biomanufacturing as the industry expands globally. With growth comes a demand for scientists, engineers, and operators who are trained in cutting-edge skills. This university is stepping up by using the lab to create a pipeline of qualified graduates who can meet that demand, helping to fill critical roles and sustain industry momentum.

Can you explain the role of state support in bringing this project to life?

State funding has been instrumental, particularly in developing a biologics development module at the university’s Biosecurity Research Institute. This module acts as a pilot production plant for research, supporting studies not just by university researchers but also by industry partners. It’s a key piece of the puzzle, connecting academic exploration with practical, scalable solutions in biomanufacturing.

What other initiatives or facilities are tied to this biomanufacturing effort?

Alongside the new lab, there have been significant upgrades to another center focused on bioprocessing and industrial value-added products. This renovated space is set to function as a drug production facility, partnering with industry to create custom vaccines and biologics, particularly for regional livestock like swine and cattle. It’s a fantastic example of how academic and industry collaboration can address specific, real-world needs.

Can you give us a sense of the scale and potential impact of this new lab space?

Certainly. The lab spans over 2,000 square feet, which is a substantial area dedicated entirely to training and innovation. That size allows for a wide range of activities and equipment, ensuring multiple students can engage in practical learning simultaneously. It’s a significant investment in creating a robust talent pool that will have a lasting impact on the biomanufacturing landscape.

What’s your forecast for the future of biomanufacturing in Kansas with initiatives like this taking shape?

I’m incredibly optimistic. With facilities like this lab, Kansas is solidifying its status as a global hub for biomanufacturing. The focus on education and industry partnership will likely attract more companies to the region, spurring economic growth and innovation. I foresee a future where Kansas not only meets the workforce demand but also sets new standards in biopharma research and production, becoming a model for other states to follow.