The biopharmaceutical industry is rapidly evolving, fueled by cutting-edge technologies and scientific breakthroughs. Novel treatments such as cell and gene therapies, biologics, and vaccines are reaching the market at unprecedented speeds. However, the rigorous journey from drug development to patient delivery demands efficiency, precision, and high-quality control. Raman spectroscopy is emerging as a pivotal technology in addressing these needs, transforming biopharma workflows by offering superior analytical capabilities.

The Biopharma Landscape and Its Challenges

Rapid Advancements and Growing Complexity

The biopharmaceutical landscape is marked by significant advancements that bring both opportunities and challenges. The US FDA’s approval of numerous new drugs in 2023 underscores the rapid pace of innovation. However, this swift progress also means that biopharma companies face increased complexity in ensuring that these novel treatments are safe and effective. Traditional analytical methods, often labor-intensive and time-consuming, struggle to keep pace with the industry’s demands, leading to delays and inconsistencies. The biopharma industry is tasked with delivering high-quality therapies to patients quickly while simultaneously maintaining stringent safety standards. This complex equation requires a technological leap to stay ahead of potential pitfalls inherent in traditional methodologies.

Traditional Methods: A Bottleneck

In the conventional biopharma workflow, traditional methods involve extensive sample preparation and lengthy run times. This not only slows down the process but also introduces potential batch-to-batch variability. The need for more efficient and reliable analytical methods is clear. As the industry seeks to optimize its processes, advanced technologies like Raman spectroscopy are stepping into the spotlight, offering faster, more accurate, and non-destructive solutions. These conventional methods often necessitate a significant investment in both time and resources, leading to bottlenecks that can hinder the expedited delivery of life-saving therapies. Addressing the inherent inefficiencies in traditional workflows is not merely an operational challenge but a critical need for patient safety and product efficacy.

Raman Spectroscopy: An Overview

Principles of Raman Spectroscopy

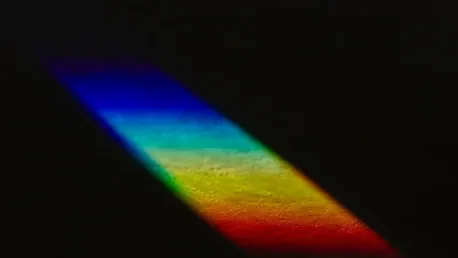

Raman spectroscopy works by using a laser to produce Raman scattering, which is then analyzed to characterize molecular structures. Each molecule generates unique Raman scattering patterns, much like fingerprints, allowing for quick and reliable material identification. This non-invasive and non-destructive method is particularly advantageous for biopharma applications, where the integrity of the sample is crucial. Raman spectroscopy operates without altering or destroying the sample, making it ideal for analyzing sensitive biological materials. The technique utilizes laser light to interact with molecular vibrations, providing a detailed spectral fingerprint unique to each substance, thereby facilitating rapid and precise analysis.

Advantages Over Traditional Methods

Compared to traditional methods, Raman spectroscopy offers several significant benefits. It provides ultra-fast chemical imaging with minimal sample preparation, enabling real-time data collection. This speed and efficiency are critical in a fast-paced industry where time-to-market can greatly impact a company’s success. Additionally, its precision ensures that quality control is maintained consistently across all stages of drug development and manufacturing. Raman spectroscopy’s ability to generate high-resolution data swiftly and accurately enhances both upstream and downstream workflows, translating into improved operational efficiencies and reduced chances for human error. The technology’s versatility and adaptability make it a fundamental tool in modernizing biopharmaceutical processes.

Integrating Raman Spectroscopy in Biopharma Processes

Enhancing Upstream Workflows

In upstream biopharma workflows, Raman spectroscopy proves invaluable in monitoring various attributes such as viable cell density and metabolic response in real-time. By detecting deviations in key biomarkers like glucose, lactate, and amino acids, researchers can quickly make necessary adjustments to optimize cell growth and protein yield. This real-time monitoring leads to better outcomes in downstream processes and ultimately, higher quality final products. The immediate feedback provided by Raman spectroscopy allows for adaptive process control, enabling scientists to fine-tune conditions dynamically, thus minimizing waste and enhancing productivity.

Streamlining Downstream Workflows

In downstream workflows, Raman spectroscopy facilitates the real-time quantification of proteins and impurities. This continuous measurement capability, especially when integrated with calibration models, allows scientists to determine metabolite levels with high accuracy. Such precise monitoring helps optimize process performance and ensures that the final biopharmaceutical formulations meet stringent quality standards. By leveraging these high-resolution insights, production teams can maintain closer control over purification processes, achieving consistent product quality. The technology’s ability to provide actionable data in real-time allows for immediate corrective measures, thereby reducing the likelihood of batch failures and costly rework.

Quality Control and Regulatory Compliance

The Role of Raman Spectroscopy in Quality Control

Quality control is a critical component of biopharma workflows, with regulatory bodies imposing rigorous safety standards. Raman spectroscopy aids in this by enabling the quick identification of chemical structures, pinpointing defects and contaminants efficiently. Its non-destructive nature allows it to be integrated throughout both upstream and downstream workflows and even during the final manufacturing stages, ensuring the consistent quality and safety of the product. The precision and speed of Raman spectroscopy make it a powerful tool for maintaining product integrity, helping biopharma companies adhere to stringent regulatory requirements and enhancing overall operational compliance.

Meeting Regulatory Requirements

The ability of Raman spectroscopy to provide real-time data aligns well with regulatory requirements, which often necessitate continuous monitoring and documentation. By leveraging this technology, biopharma companies can ensure compliance with regulatory standards while also enhancing their operational efficiency. This dual benefit makes Raman spectroscopy an indispensable tool in modern biopharma workflows. The robust data generated by Raman spectroscopy supports comprehensive documentation, facilitating the submission of accurate and timely reports to regulatory agencies. This capability not only ensures compliance but also builds regulatory confidence, potentially expediting the approval process for new therapies.

Future Prospects of Raman Spectroscopy in Biopharma

Driving Industry Innovation

As biopharma continues to push the boundaries of medicine, the need for robust analytical tools becomes even more pronounced. Raman spectroscopy is poised to play a key role in this evolution, driving further innovations and enabling the efficient development of next-generation therapies. Its integration into Process Analytical Technology (PAT) frameworks exemplifies how advanced analytical methods can significantly enhance biopharma efficiency. By embracing these cutting-edge technologies, the industry can accelerate innovation cycles and bring novel treatments to market more rapidly, thereby improving patient outcomes and staying ahead of competitive pressures.

Research and Collaboration for Broader Adoption

For broader adoption of Raman spectroscopy in biopharma, ongoing research and collaboration are essential. Academic institutions, industry players, and regulatory bodies must work together to refine these technologies and establish best practices. Such collective efforts will pave the way for widespread implementation, ultimately benefiting the entire biopharma ecosystem and enhancing the delivery of life-saving therapies to patients. Collaborative research initiatives can spur technological advancements, while industry partnerships can drive the practical application of Raman spectroscopy in large-scale production environments. Together, these efforts will foster an ecosystem that supports continuous improvement, innovation, and excellence in biopharmaceutical manufacturing.

By focusing on these crucial aspects, Raman spectroscopy is not just meeting current biopharma needs but is also setting the stage for future advancements, ensuring that the industry continues to thrive in its mission to provide high-quality, safe, and effective treatments.

Conclusion

The biopharmaceutical industry is experiencing rapid advancements, driven by groundbreaking technologies and scientific discoveries. Innovative treatments such as cell therapies, gene therapies, biologics, and vaccines are being introduced to the market faster than ever before. Nevertheless, the stringent process from drug development to patient delivery requires meticulous efficiency, precision, and superior quality control.

One technology that is making a significant impact in meeting these demands is Raman spectroscopy. This analytical tool is becoming essential in the biopharmaceutical sector for its advanced capabilities. Raman spectroscopy offers unparalleled precision in analyzing the molecular composition of substances, which is critical for ensuring the safety and efficacy of biopharmaceutical products.

By integrating Raman spectroscopy into their workflows, biopharmaceutical companies can streamline processes, reduce costs, and improve overall productivity. This technology not only accelerates the pace of bringing new treatments to market but also enhances the reliability of quality control measures. As a result, Raman spectroscopy is poised to play a crucial role in the continued evolution of the biopharmaceutical industry.