The biopharmaceutical industry is undergoing a significant transformation as it seeks to develop affordable treatments for unmet medical needs. Amidst this change, manufacturers are being pushed to cut costs and implement sustainable practices. Tosoh Bioscience stands out as a leader in sustainable biomanufacturing, leveraging innovative strategies to advance process robustness, efficiency, and flexibility while maintaining environmental responsibility. Tosoh’s approach involves an intricate balance of maintaining high production standards, embracing new therapeutic modalities, and integrating sustainable practices into their core operations.

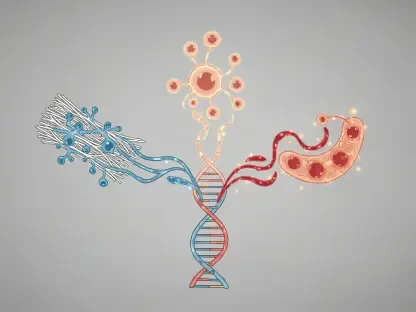

As the sector moves beyond monoclonal antibodies (mAbs) and delves into cell and gene therapies, Tosoh is adapting its manufacturing capabilities to accommodate these cutting-edge treatments. This transition necessitates the adoption of flexible and scalable systems that can handle multiple product types within a single facility. Tosoh recognizes that to meet these new demands, biomanufacturers must overcome unique production challenges and ensure rigorous quality controls. By innovating with flexible, modular systems that cater to the complexities of contemporary therapeutics, Tosoh is maintaining consistency and quality across its broadening production spectrum.

Embracing New Therapeutic Modalities

The biopharmaceutical sector is diversifying beyond traditional monoclonal antibodies and increasingly focusing on new therapeutic approaches such as cell and gene therapies. This shift aligns with the growing number of FDA approvals for biologics, highlighting the industry’s direction toward personalized medicine. Tosoh Bioscience identifies this trend and is strategically adapting its manufacturing capabilities to effectively accommodate these innovative therapies. As cell and gene therapies become prevalent, biomanufacturers face the challenge of adopting different manufacturing techniques and stringent quality controls. Tosoh’s flexible, modular systems are uniquely designed to handle multiple product types efficiently within the same facility, addressing the critical needs of these complex therapies while maintaining consistency and high-quality standards.

Further compounding the need for innovation are the unique production challenges that these new therapeutic modalities bring. Conventional approaches to manufacturing are often inadequate for the specialized demands of cell and gene therapies. Tosoh’s approach centers around the implementation of advanced manufacturing techniques that can adapt to these requirements. This includes integrating modular designs that allow for smooth transitions between different types of products without compromising on quality or efficiency. Through such adaptive measures, Tosoh ensures that it remains at the forefront of the biopharmaceutical industry, capable of responding swiftly to emerging therapeutic trends and maintaining a high standard of product quality.

Commitment to Sustainability

Sustainability is a core value at Tosoh Bioscience, integrated across all levels of operation. From product development to manufacturing processes, the company emphasizes eco-friendly practices. This commitment not only reduces environmental impact but also enhances operational efficiency. Key to this strategy is the adoption of continuous manufacturing, which optimizes resource utilization and lowers waste, making production more sustainable. Continuous manufacturing plays a vital role in sustainable biomanufacturing. By producing therapies in a continuous flow rather than in traditional batch processes, Tosoh minimizes material waste and energy consumption. This method also improves product yield and consistency, further supporting the delivery of cost-effective medicines. Through these initiatives, Tosoh not only meets regulatory sustainability mandates but also anticipates future industry trends.

Continuous manufacturing, a cornerstone of sustainable biomanufacturing, allows Tosoh to optimize its production processes, minimizing material waste and reducing energy consumption. This method, as opposed to traditional batch processes, offers a more efficient and environmentally friendly way to produce therapies. By maintaining a continuous flow of production, Tosoh not only reduces its environmental footprint but also enhances the consistency and yield of its products. These improvements are crucial for delivering cost-effective medicines while adhering to stringent environmental standards. Through this proactive approach, Tosoh Bioscience not only complies with existing sustainability regulations but positions itself to lead the industry in anticipating and meeting future demands for sustainable practices.

Technological Innovations Driving Efficiency

Advanced technologies are central to Tosoh Bioscience’s strategy for improving process efficiency and flexibility. Among these innovations are single-use systems, process intensification, and enhanced process analytics. Single-use systems, for instance, reduce the need for extensive cleaning and sterilization, minimizing downtime and contamination risk. These systems can be rapidly deployed, making them ideal for scalable production. Process intensification streamlines manufacturing by maximizing productivity within a smaller operational footprint. Tosoh’s development of flexible Multi Column Chromatography (MCC) skids, such as the Octave BIO for process development and Octave™ PRO for GMP-scale production, exemplifies this approach. These technologies enable higher throughput with reduced resource inputs, aligning with both economic and environmental goals.

In addition to single-use systems and process intensification, Tosoh Bioscience leverages enhanced process analytics to drive efficiency and flexibility in biomanufacturing. These advanced analytics tools are crucial for monitoring and optimizing various stages of production. By incorporating robust data analytics, Tosoh can ensure real-time quality control and swiftly identify potential issues before they escalate, thereby reducing downtime and enhancing overall efficiency. The combination of these technologies not only streamlines production but also makes it more versatile, capable of adapting to the evolving needs of the biopharmaceutical market. Such technological advancements are essential for maintaining Tosoh’s position as a leader in innovative and sustainable biomanufacturing practices.

Strategic Partnerships and Collaborations

Partnerships are crucial for driving innovation in biomanufacturing. Tosoh Bioscience collaborates with industry leaders to advance its technologies and expand its capabilities. For example, its partnership with Catalent Pharma/Novo demonstrates a commitment to developing sophisticated MCC technology. These collaborations facilitate knowledge exchange and drive forward integrated, automated processes such as those seen in the ECOnti project led by enGenes Biotech GmbH. Collaborative efforts enable Tosoh to stay at the forefront of biomanufacturing innovation. By working with experts in various fields, the company can integrate diverse technological advancements into its operations. This not only accelerates the development of new processes but also ensures they are robust, scalable, and environmentally sustainable, setting new standards for the industry.

Engaging in strategic partnerships allows Tosoh Bioscience to leverage external expertise and drive forward innovation collaboratively. These partnerships enable the company to incorporate cutting-edge technologies and methodologies that may otherwise be beyond its immediate scope. A notable example is Tosoh’s involvement in the ECOnti project, which aims to develop integrated, automated manufacturing processes. Such collaborations are invaluable for pushing the boundaries of what is possible in biomanufacturing. By pooling resources and expertise, Tosoh and its partners can achieve breakthroughs that benefit the entire industry. This collective effort ensures that innovative, sustainable solutions are developed and implemented, helping Tosoh maintain its leadership in biomanufacturing excellence.

Ensuring Business Continuity and Resilience

The COVID-19 pandemic underscored the importance of supply chain resilience and business continuity. In response, Tosoh Bioscience has expanded its manufacturing capabilities, ensuring a robust supply chain that can withstand global disruptions. New manufacturing facilities across multiple locations guarantee the company can meet demand, without compromising quality or service reliability. This strategic expansion underscores Tosoh’s dedication to maintaining continuous supply and adapting swiftly to market changes. By increasing production capacity and diversifying its manufacturing sites, Tosoh enhances its ability to respond to unexpected challenges. This approach not only supports ongoing operations but also positions the company to capitalize on future growth opportunities within the biopharmaceutical industry.

To further ensure business continuity, Tosoh Bioscience focuses on strategic planning and proactive risk management. The company’s expansion into multiple geographic locations mitigates the risks associated with potential regional disruptions. This geographical diversification is complemented by investments in advanced manufacturing technologies and practices, which collectively enhance Tosoh’s operational resilience. By anticipating and preparing for various challenges, Tosoh can maintain its high standards of quality and service, assuring stakeholders of its reliability. This forward-thinking approach not only addresses current industry needs but also sets a strong foundation for future growth and sustainability. Tosoh’s commitment to resilience ensures it remains a dependable leader in the biopharmaceutical sector.

Looking to the Future: Innovation and Expansion

The biopharmaceutical industry is experiencing a profound change as it strives to create cost-effective treatments for unmet medical needs. Amidst this evolution, manufacturers are under pressure to reduce expenses and adopt sustainable practices. Tosoh Bioscience emerges as a leader in green biomanufacturing, utilizing innovative strategies to enhance process robustness, efficiency, and flexibility while prioritizing environmental sustainability. Tosoh balances high production standards with the integration of new therapeutic modalities and sustainable practices into its core operations.

As the industry progresses beyond monoclonal antibodies and explores cell and gene therapies, Tosoh is upgrading its manufacturing capabilities to support these advanced treatments. This shift demands flexible, scalable systems capable of handling multiple product types within a single facility. Tosoh understands that meeting these new requirements involves overcoming distinct production challenges and implementing stringent quality controls. By pioneering modular systems tailored to the complexities of modern therapeutics, Tosoh ensures consistent quality and performance across its expanding production landscape.