The biopharmaceutical industry has been shaken by the European Union’s recent ban on Triton X-100, a detergent essential for preventing viral contamination in biologics and plasma-derived products. Since its enactment in 2021, this regulatory change has catalyzed a worldwide search for alternatives, highlighting a dynamic shift towards environmental sustainability and innovative solutions.

Global Impact of the Triton X-100 Ban

Interconnected Nature of the Biopharma Industry

The EU’s ban on Triton X-100 is a prime example of how regional regulations can create global repercussions, especially in an interconnected industry like biopharma. As Garima Sinha, PhD, a lead application scientist at Croda, points out, the initial reluctance to adapt to this regulation outside of the EU underscored the complex and extensive investment companies had made in optimizing Triton X-100-based processes. The regulatory change prompts industries across continents to adjust, making the transition a significant operational and economic hurdle.

This phenomenon showcases how deeply integrated the biopharma sector is, with regulatory shifts in one region necessitating global adjustments to ensure compliance. Companies worldwide, having invested substantial resources into processes involving Triton X-100, find themselves in a challenging position. The need to maintain product quality while adhering to new environmental standards has driven a universal search for high-performing alternatives, reflecting both the industry’s resilience and the imperative for innovation in the face of stringent regulations.

Industry Resistance and Adaptation

The hesitation to transition away from Triton X-100 is rooted in the extensive time and resources dedicated to optimizing its application in biopharmaceutical processes. Despite the understandable resistance, the imperative to comply with new regulations cannot be ignored, catalyzing innovative efforts across the industry. Sinha highlights that adapting to change is challenging but necessary, as companies apprehensively explore the extensive search for viable alternatives.

This search reveals the biopharma industry’s resilient and adaptable nature, having faced numerous regulatory hurdles in the past. While transitioning from Triton X-100 involves significant operational complexity and potential economic implications, the emergence of innovative solutions underscores the industry’s ability to turn challenges into opportunities for progress. The industry’s capacity to innovate in response to regulatory demands is evident as it navigates the complexities of developing alternatives without sacrificing product efficacy and safety.

The Push for Sustainable Alternatives

Environmental Responsibility in Biopharma

The shift away from Triton X-100 aligns with a broader movement towards environmental sustainability within the biopharmaceutical industry. Companies like Croda are leading the charge, leveraging their extensive catalog of specialty chemicals to identify eco-friendly substitutes that do not compromise on performance. This transition underscores a growing awareness of the environmental impacts of industrial processes and a collective commitment to mitigating these effects.

The biopharmaceutical sector’s efforts to balance efficacy with sustainability reflect a more nuanced understanding of environmental responsibility. The development of high-performing, environmentally friendly alternatives to Triton X-100 illustrates a conscious effort to integrate eco-friendly practices into rigorous manufacturing standards. Companies are recognizing the dual imperatives of maintaining high-quality products while reducing their environmental footprint, a balance that is increasingly becoming a defining characteristic of the industry.

Croda’s Role in Innovation

Croda’s development of Virodex TXR-1 and TXR-2 exemplifies a proactive response to the EU ban, marking a significant progression in the quest for high-performing alternatives to Triton X-100. These chemicals not only match but potentially exceed the efficacy of Triton X-100, offering robust performance while adhering to new environmental standards. Dr. Wenyi Yee, Croda’s research manager, emphasizes the significance of these alternatives, which are backed by robust independent data. This innovation highlights a broader trend towards rapid development and deployment of sustainable solutions in response to regulatory changes.

Croda’s proactive measures underscore the importance of maintaining rigorous standards while navigating the transition towards environmentally friendly alternatives. The company’s focus on developing Virodex reflects a broader industry trend towards sustainability without sacrificing product efficacy. This period of transition emphasizes the need for innovative solutions that can meet regulatory requirements and maintain the high standards expected in biopharmaceutical manufacturing. Croda’s success with Virodex serves as a model likely to inspire similar efforts across the industry.

Challenges and Novel Approaches

Analytical Testing and Validation

The transition away from Triton X-100 involves navigating the complexities of stringent analytical testing and validation. Ensuring that new detergents do not contaminate final drug products requires meticulous testing, and companies like Croda collaborate with customers for product trials to guarantee reliability and safety. Croda’s development of techniques to detect Virodex at parts per billion (PPB) levels underscores the need for precision in biopharmaceutical manufacturing, reflecting the industry’s rigorous standards.

These meticulous approaches resonate with the industry’s commitment to reliability and safety, essential for maintaining product integrity while adhering to new regulations. Analytical testing and validation are crucial steps in ensuring that new chemicals can be seamlessly integrated into existing manufacturing processes without compromising product quality. Croda’s collaboration with customers highlights the industry’s collaborative spirit and dedication to maintaining high standards through innovation and adaptation.

Maintaining Process Integrity

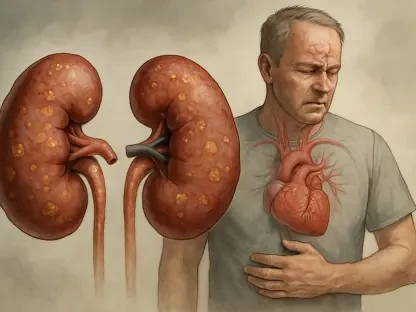

While altering pH levels or using different detergents present viable options, detergents often provide superior robustness compared to pH changes, which can pose risks such as protein aggregation. Sinha notes the potential disadvantages of pH alterations, reinforcing the industry’s preference for reliable detergent alternatives. Maintaining process integrity while complying with environmental standards illustrates the biopharmaceutical sector’s proactive stance in finding suitable substitutes for Triton X-100.

The search for reliable and sustainable alternatives to Triton X-100 is crucial for maintaining the high standards expected in biopharmaceutical manufacturing. Companies are exploring various approaches to ensure product efficacy and safety, reflecting their commitment to overcoming regulatory challenges and maintaining process integrity. The preference for robust detergent alternatives underscores the industry’s dedication to finding sustainable solutions that do not compromise the quality and safety of biopharmaceutical products.

Broader Implications and Future Trends

Industry-Wide Adaptation and Collaboration

The Triton X-100 ban has underscored the collaborative spirit within the biopharmaceutical industry, with companies pooling resources and knowledge to navigate regulatory changes. This cooperative approach signifies an industry-wide adaptation, as firms strive to develop environmentally sustainable and high-performing alternatives to Triton X-100. Companies like Croda lead by example, fostering a shared goal of integrating eco-friendly practices into rigorous manufacturing standards.

The industry’s collective effort to adapt and innovate in response to the Triton X-100 ban demonstrates a commitment to maintaining product quality and compliance while addressing environmental concerns. This collaborative spirit reflects a broader trend towards sustainability and shared responsibility within the biopharmaceutical sector. Companies are recognizing the importance of working together to overcome regulatory challenges and drive innovation, ensuring that the industry continues to progress towards environmentally responsible practices.

Future Outlook and Continued Innovation

The biopharmaceutical industry’s response to the Triton X-100 ban heralds an era of continued innovation, driven by evolving regulatory landscapes and a push for sustainable practices. As companies align with new environmental standards, the quest for eco-friendly solutions promises a future where environmental responsibility and biopharmaceutical efficacy go hand in hand. Croda’s success with Virodex illustrates a model likely to be mirrored by other industry players, fostering a culture of innovation and sustainability.

The ongoing efforts to develop and implement sustainable alternatives to Triton X-100 reflect the biopharmaceutical sector’s commitment to balancing product efficacy with environmental responsibility. The continued innovation in response to regulatory changes underscores the industry’s resilience and adaptability, ensuring that high standards are maintained while addressing environmental concerns. The future of biopharmaceutical manufacturing is likely to be characterized by a harmonious blend of sustainability and efficacy, driven by the industry’s dedication to overcoming challenges and embracing innovative solutions.

Conclusion

The biopharmaceutical industry has experienced significant upheaval following the European Union’s recent prohibition of Triton X-100. This detergent has been crucial in preventing viral contamination in both biologics and plasma-derived products. Enforced in 2021, this regulatory change has ignited a global quest for suitable alternatives. The ban underscores a broader movement toward environmental sustainability and the pursuit of new, innovative solutions.

Pharmaceutical companies and research institutions worldwide are now investing considerable resources to identify and develop effective substitutes capable of matching Triton X-100’s performance without its environmental drawbacks. This shift has not only spurred technological advancements but has also opened up discussions about regulatory and manufacturing processes within the industry. Environmental advocates view the ban as a significant step forward, pushing the industry to align more closely with green chemistry principles. As the search for alternatives intensifies, the biopharmaceutical industry finds itself at a pivotal juncture, poised between maintaining product safety and embracing eco-friendly practices.