At the recent BPI Europe 2024 conference, a landmark discussion led by Uwe Buecheler from Boehringer Ingelheim marked the dawn of a new chapter in biopharmaceuticals. Described as the ‘third wave’ of biologics, it signifies an era brimming with groundbreaking therapeutic innovations that stand to revolutionize healthcare. These upcoming treatments, while extraordinarily promising, also introduce unprecedented levels of complexity in their Chemistry, Manufacturing, and Controls (CMC) processes. As the industry stands at this pivotal junction, companies are tasked with a critical challenge: to adeptly steer through and master the nuances of this advanced biomanufacturing terrain. The shift is monumental, and the biopharmaceutical sector must be both agile and strategic to harness the full potential of this transformative wave.

The Journey Through Waves in Biomanufacturing

Biomanufacturing has traversed a fascinating path marked by two distinct waves before arriving at the threshold of today’s complex era. The initial wave, from 1997 to 2010, heralded TNF inhibitors and a proliferation of cancer-fighting monoclonal antibodies. Following this, the next wave persisted until 2020, focusing on refining antibody technologies and introducing derivatives. The culmination of these developments has solidified bioprocessing as a cornerstone of medical innovation, yielding treatments with far-reaching impacts.

The Rise of the Third Wave

As the biopharmaceutical sector pivots towards the frontier of medical innovation, it grapples with the emerging wave of advanced therapies that have surged since 2020. These therapies challenge the status quo with sophisticated approaches to medicine, featuring cutting-edge categories such as Antibody-Drug Conjugates (ADCs), genomic interventions through RNA/DNA therapies, Cell and Gene Therapies (CGTs), and beneficial microbiome products. These new therapeutic avenues demand reinvention of the Chemistry, Manufacturing, and Controls (CMC) process, testing the limits of traditional manufacturing systems. Notably, experts like Buecheler highlight ADCs and CGTs as pioneers in this transformative era, driving the requirement for innovative manufacturing practices tailored to their intricate nature. This evolution within biopharmaceuticals marks both an exciting prospect and a complex challenge in delivering next-generation treatments to patients.

Overcoming the Challenges of Complexity

ADCs, despite being rooted in the familiar terrain of antibodies, introduce complexities through the incorporation of intricate toxic payloads and linkers. CGTs, on the other hand, represent a more radical departure from established methods, presenting novel issues like host immunity, cell lysis, and the threat of replication-competent viruses. These challenges are symptomatic of the growing pains necessitating revolutionary approaches and advanced problem-solving skills within the biotech sphere.

Revolutionary Technologies and Infrastructure

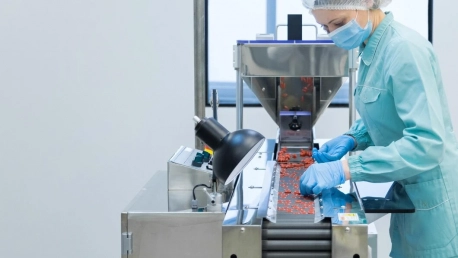

Amidst evolving challenges, the biopharmaceutical sector is shifting gears. The adoption of single-use systems and modular production solutions is picking up speed due to their flexibility and capability for rapid scaling. These approaches are now commonplace as they align with the industry’s dynamic needs. Contract Development and Manufacturing Organizations (CDMOs) are also taking on a crucial role, particularly for small biotech companies that require support to bring innovations to market. This symbiosis is vital in an era where technological and regulatory complexities intensify, and the integration of novel solutions is paramount. The partnership between CDMOs and biotech firms underscores a strategic alliance in the relentless pursuit of medical breakthroughs, ensuring that the path from lab to patient is both efficient and adaptable to ever-changing global health demands.

The Future of DNA and RNA Therapies

An emerging trend is the shift from virus-based treatments to therapies that modulate DNA and RNA, signaling a significant pivot in biomanufacturing strategies. Over a thousand programs are now devoted to these kinds of therapies, which forecasts a future demanding heightened adaptability and continuous innovation. The industry, thus, is at a juncture where it must not only meet the current manufacturing demands but also anticipate and prepare for the modalities of tomorrow.

Preparing for What’s Next in Biomanufacturing

Facing an onslaught of breakthroughs, biopharmaceutical firms must stay alert and agile, cultivating a culture that espouses innovation. Present production dilemmas are being confronted with determination, yet the focus must also extend beyond current challenges, preparing the biomanufacturing sector for the intricate demands that future biologic medicines will present. This strategic mix of readiness and forward-thinking will dictate triumph in the evolving realm of biopharmaceuticals.Crafting a robust response to this innovation surge, these companies cannot afford to rest on their laurels. They must pivot and adapt, crafting landscapes that nurture progressive ideas. As they grapple with existing manufacturing complexities, it’s crucial they also peer into the future, equipping their biomanufacturing frameworks to handle the nuanced needs tomorrow’s biologic treatments will introduce. Such a dynamic approach, balancing immediate action with strategic long-term planning, is critical for thriving in the ever-changing biopharmaceutical field.