The medical device manufacturing sector is undergoing a seismic shift, with automation emerging as the cornerstone of innovation and efficiency as the industry looks toward 2035, driven by the urgent need to meet rising global healthcare demands. Projections from recent market analyses indicate that the automation market within this field is set to surpass $9 billion in value this year, with significant growth expected over the next decade. Technologies such as robotics, Artificial Intelligence (AI), and the Industrial Internet of Things (IIoT) are not merely enhancing production—they are redefining it. These advancements address the pressing need for precision in an era where devices are becoming increasingly complex and miniaturized, while also meeting the demand for scalability amid rising global healthcare needs. However, this transformation is not without hurdles, as manufacturers grapple with regulatory pressures and external disruptions like trade tariffs. The journey to fully automated production promises to reshape how medical devices are designed and delivered, setting a new standard for quality and competitiveness in a high-stakes industry.

Driving Precision and Scalability

The push for automation in medical device manufacturing is largely fueled by the intricate nature of modern devices, which often require precision beyond human capability. Items like implantable sensors and micro-surgical instruments demand exacting standards to ensure functionality and safety, areas where manual processes frequently fall short. Robotics and sensor-driven systems have become indispensable, offering unmatched repeatability and accuracy that minimize defects and elevate product reliability. This technological leap is especially vital as innovation accelerates, with devices shrinking in size yet growing in complexity. Automation ensures that manufacturers can keep pace with these advancements, producing consistent results that meet the stringent expectations of healthcare providers and patients alike. Without such systems, maintaining quality across high-volume production runs would be nearly impossible, risking both reputation and regulatory standing in a field where errors carry profound consequences.

Another critical advantage of automation lies in its ability to balance cost efficiency with the need to scale operations. As global demand for medical devices surges, manufacturers face the challenge of increasing output without inflating expenses or compromising on quality. Automated systems streamline essential processes like assembly, packaging, and inspection, significantly reducing labor costs and the potential for human error. In sterile environments such as cleanrooms, automation also mitigates contamination risks, a non-negotiable factor in medical production. Additionally, the flexibility of programmable platforms allows for rapid product changeovers, enabling companies to manage diverse product lines and adapt to shorter innovation cycles with ease. This capability is a lifeline for businesses navigating competitive markets, ensuring they can respond swiftly to evolving consumer needs while maintaining profitability. The economic benefits of automation, therefore, extend far beyond initial savings, positioning it as a strategic tool for long-term growth.

Overcoming Regulatory and Global Challenges

Regulatory compliance remains a cornerstone of medical device manufacturing, where adherence to global standards is not just a requirement but a safeguard against costly setbacks. Automation plays a pivotal role in meeting these demands by integrating real-time analytics and cloud-based data management into production workflows. Such systems ensure traceability at every stage, from raw materials to finished products, making audits seamless and reducing the risk of non-compliance penalties or recalls. Predictive maintenance features further enhance reliability by minimizing unexpected downtime, ensuring that operations consistently align with quality benchmarks. In an industry under constant scrutiny, the ability to maintain detailed records and anticipate issues before they arise offers a competitive edge. Automation transforms compliance from a burden into a manageable, even advantageous, aspect of manufacturing, allowing companies to focus on innovation rather than risk mitigation.

External pressures, such as U.S. trade tariffs on components sourced from regions like China and the European Union, introduce additional complexity to the automation landscape. These tariffs have inflated costs for essential parts like sensors and microelectronics, creating delays that disrupt deployment timelines. In response, many manufacturers are rethinking their supply chain strategies, turning to nearshoring and reshoring to reduce dependency on volatile international markets. This shift, while challenging in the short term, has accelerated the adoption of advanced automation as a means to build operational resilience. By investing in technologies that lessen reliance on imported components and streamline production, companies are better equipped to weather geopolitical uncertainties. This adaptation highlights how external obstacles can spur innovation, pushing the industry toward more self-sufficient and robust manufacturing models that prioritize long-term stability over temporary cost savings.

Envisioning Smart Factories and Global Expansion

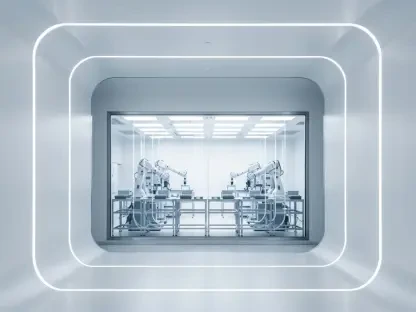

The concept of smart factories, underpinned by Industry 4.0 principles, is rapidly becoming the blueprint for the future of medical device manufacturing. Technologies like AI, robotics, and IIoT are central to this evolution, enabling data-driven decision-making through real-time analytics and digital twins. These tools optimize workflows, predict quality issues before they occur, and reduce waste, ultimately enhancing productivity across the board. The industry consensus suggests that by 2035, fully autonomous production environments will be the norm, minimizing human intervention and maximizing efficiency. Such a shift not only improves operational uptime but also redefines how manufacturers approach design and quality control, embedding intelligence into every facet of the process. As smart factories gain traction, they promise to set a new benchmark for what’s possible, turning manufacturing facilities into hubs of innovation that can adapt to challenges in real time.

Emerging markets, particularly in the Asia-Pacific region, present a significant growth frontier for automation in medical device production. As healthcare infrastructure expands in these areas, so does the demand for high-quality devices, creating a pressing need for scalable solutions. Automation offers local manufacturers the ability to meet international standards while keeping costs competitive, bridging the gap between global expectations and regional capabilities. This trend reflects a broader move toward localized production within a globalized framework, allowing companies to serve diverse markets without sacrificing efficiency or quality. The potential in these regions underscores automation’s role as a catalyst for accessibility, ensuring that life-saving technologies reach populations previously underserved by advanced medical solutions. By capitalizing on these opportunities, the industry can drive both economic growth and improved health outcomes on a worldwide scale.

Building a Resilient Future

Reflecting on the strides made, it’s clear that automation had already begun transforming medical device manufacturing into a more precise and efficient field by the mid-2020s. The integration of robotics, AI, and IIoT had addressed critical pain points like device complexity and regulatory demands, setting a foundation for unprecedented scalability. Yet, challenges such as high initial costs and supply chain disruptions due to trade tariffs had tested the industry’s adaptability, pushing it to innovate under pressure. Looking ahead, stakeholders should prioritize strategic investments in flexible automation systems that accommodate custom production needs while fostering partnerships to diversify supply chains. Embracing smart factory principles and targeting growth in emerging markets will be key to sustaining momentum through 2035. By focusing on these actionable steps, the industry can solidify automation as a pillar of resilience, ensuring that future advancements in medical technology are both accessible and sustainable for generations to come.