The biopharmaceutical manufacturing sector stands at the brink of a revolution, driven by the relentless pursuit of speed, safety, and scalability. The emergence of new therapeutic modalities, coupled with the increasing demand for rapid and cost-effective production solutions, has necessitated a paradigm shift in how treatments are developed and manufactured. Central to this transformation is the role of automation, which is paving the way for unprecedented efficiencies and quality standards. Automation stands as a cornerstone in the drive to innovate, enabling biopharmaceutical companies to address contemporary challenges while meeting escalating consumer and regulatory demands.

The Need for Speed and Efficiency

In today’s fast-paced biopharmaceutical landscape, the ability to produce therapies quickly and efficiently is paramount, going beyond just keeping up with competitors to saving lives and addressing urgent health crises. For instance, the timely development and distribution of COVID-19 vaccines highlighted the need for swift and efficient manufacturing processes. As such, biopharmaceutical companies are increasingly investing in automated systems that streamline production workflows, minimize human error, and accelerate the time-to-market for new therapies.

Automation in biopharmaceutical manufacturing enhances efficiency by automating repetitive and time-consuming tasks. Robotic arms, automated storage and retrieval systems, and high-throughput screening tools are becoming staples in modern manufacturing facilities. These innovations reduce the reliance on manual labor, thereby decreasing the risk of contamination and improving overall process consistency. By minimizing the margin for error, automation creates a more reliable production environment, leading to consistently high-quality products.

Furthermore, automation facilitates scalability in production. As demand for biopharmaceuticals grows, the ability to scale manufacturing processes quickly and seamlessly becomes crucial. Automated systems can be easily adjusted to operate at different scales, ensuring that production can be ramped up or down based on market needs without compromising quality or efficiency. This flexibility is particularly vital in dealing with sudden surges in demand, such as during public health emergencies or pandemics. The ability to quickly pivot and adapt to changing conditions gives companies a competitive edge while ensuring that critical therapies reach patients in need promptly.

Enhancing Safety and Quality Control

Safety is a cornerstone of biopharmaceutical manufacturing, given the potential risks associated with the production of complex biological therapies. Automation plays a critical role in enhancing safety by reducing human intervention and thus minimizing contamination risks. Automated systems can perform tasks with high precision and consistency, ensuring that manufacturing protocols are adhered to without deviation. This level of control is essential in maintaining the integrity of biopharmaceutical products, which, by their nature, are often sensitive and require exacting standards.

One of the significant advancements in this area is the development of automated cell isolation and bead removal technologies. For example, the Gibco CTS DynaCellect Magnetic Separation System enables automated cell isolation with unparalleled efficiency and accuracy. By automating these critical steps, the risk of contamination is significantly reduced, leading to safer therapeutic products. This technology exemplifies how automation can directly contribute to improving both the safety and efficacy of biopharmaceutical therapies, making them more reliable and effective.

Automation also improves quality control by enabling real-time monitoring and data collection throughout the manufacturing process. Advanced sensors and analytical tools can detect deviations from established quality standards, allowing for immediate corrective actions. This level of oversight ensures that every batch of biopharmaceutical products meets stringent regulatory requirements, thereby safeguarding patient safety. Continuous monitoring facilitated by automation not only improves current quality control measures but also helps in identifying patterns that could lead to future improvements, creating a cycle of ongoing enhancement in manufacturing standards.

Addressing Challenges in Cell and Gene Therapy

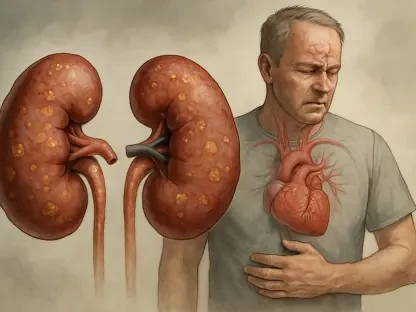

Cell and gene therapy represent some of the most promising advancements in modern medicine, offering potential cures for previously untreatable conditions. However, the manufacturing of these therapies presents unique challenges, including high production costs and complex processes. Automation is proving to be a game-changer in overcoming these hurdles. The multi-step nature of cell and gene therapy production is labor-intensive and prone to variability, which can impact the consistency and efficacy of the final product.

The manufacturing process for cell and gene therapies involves multiple intricate steps, from cell isolation and expansion to genetic modification and final product formulation. Each of these steps is labor-intensive and prone to variability, which can impact the consistency and efficacy of the final product. Automation streamlines these processes, ensuring that each step is performed with high precision and minimal variability. By reducing manual interventions, automation lowers the risk of errors and inconsistencies, ultimately leading to more effective therapies.

For example, the introduction of the Gibco™ CTS™ Detachable Dynabeads™ has revolutionized cell therapy manufacturing. This technology allows for the active and controlled release of cells, simplifying the process and improving consistency. Such innovations not only enhance the efficiency of cell therapy production but also reduce costs, making these cutting-edge treatments more accessible to patients. The ability to automate processes also enables quicker scaling of production, addressing the growing demand for these advanced therapies.

The Push for Sustainable Manufacturing

Sustainability is an increasingly important consideration in biopharmaceutical manufacturing. As companies strive to meet environmental, social, and corporate governance (ESG) goals, automation emerges as a key enabler of eco-friendly manufacturing practices. Automated systems are designed to optimize resource usage, reduce waste, and minimize the environmental footprint of production processes. This focus on sustainability is becoming more than just a regulatory requirement; it is evolving into a core component of responsible corporate stewardship.

Thermo Fisher Scientific exemplifies this commitment to sustainability with initiatives aimed at reducing hazardous material use and resource consumption. By integrating automated systems, manufacturers can achieve greater precision in material handling, thereby reducing waste and promoting more efficient use of raw materials. Additionally, automated processes can be designed to be energy-efficient, further contributing to sustainability goals. These advancements are not only beneficial for the environment but also enhance the operational efficiency and cost-effectiveness of manufacturing processes.

Moreover, automation supports the development of closed-system manufacturing processes, which are inherently more sustainable. Closed systems minimize the risk of contamination and reduce the need for extensive cleanroom facilities, thereby lowering energy consumption. These systems also facilitate the recycling and reuse of materials, aligning with circular economy principles and enhancing the overall sustainability of biopharmaceutical manufacturing. By prioritizing sustainability, companies can align their operations with broader global efforts to combat climate change and promote environmental stewardship.

Integrating Physical and Digital Systems

The future of biopharmaceutical manufacturing lies in the seamless integration of physical and digital systems. This fusion, often referred to as Industry 4.0, leverages the power of the Internet of Things (IoT), big data, and artificial intelligence (AI) to create smart manufacturing environments. In such setups, automated equipment and digital technologies work in concert to optimize every aspect of the production process. The integration of these technologies promises to revolutionize the industry by enhancing efficiency, accuracy, and overall process intelligence.

Industry 4.0 enables real-time data collection and analysis, facilitating more informed decision-making. Digital twins, which are virtual replicas of physical assets, allow for the simulation and optimization of manufacturing processes before implementation in the real world. This reduces the risk of errors and accelerates the adoption of new technologies and methodologies. The ability to predict and mitigate issues before they occur is a significant advantage, providing manufacturers with a proactive approach to quality control and process optimization.

In addition, predictive maintenance powered by AI and IoT sensors helps in identifying potential equipment failures before they occur, minimizing downtime and ensuring continuous operation. This not only enhances productivity but also extends the lifespan of manufacturing equipment, contributing to cost savings. The combined power of physical and digital systems thus offers a comprehensive approach to revolutionizing biopharmaceutical manufacturing, driving the industry towards a future characterized by unprecedented efficiency, reliability, and adaptability.

Conclusion

The biopharmaceutical manufacturing sector is on the cusp of a significant transformation fueled by the unyielding quest for faster, safer, and scalable solutions. The advent of novel therapeutic modalities, alongside the surging demand for quick and cost-effective production methods, calls for a fundamental shift in treatment development and manufacturing approaches. Central to this evolution is the integration of automation, which is setting new benchmarks for efficiency and quality. Automation has become a pivotal element in the drive for innovation, allowing biopharmaceutical companies to navigate contemporary challenges while simultaneously adhering to stricter consumer and regulatory expectations.

Automation not only accelerates production timelines but also ensures higher standards of safety and consistency. By automating critical processes, companies can reduce human error, streamline operations, and achieve superior reproducibility. This shift is essential for meeting the growing need for personalized medicine, where treatments are tailored to individual patients. As the biopharmaceutical industry continues to embrace automation, it will unlock new levels of productivity and precision, ultimately enhancing the overall effectiveness and accessibility of medical treatments. By integrating advanced technologies, the sector is poised to deliver on the promise of next-generation therapies.