The upstream bioprocessing market is experiencing unprecedented growth, driven by a confluence of factors that are reshaping the landscape of biopharmaceutical production. Valued at 22.79 billion USD in 2023, the market is projected to surge to 82.10 billion USD by 2032, expanding at a compound annual growth rate (CAGR) of 15.35% from 2024 to 2032. This article delves into the key drivers behind this rapid expansion, highlighting the role of innovation, flexibility, and technological advancements.

Innovation and Flexibility in the Upstream Bioprocessing Market

Increasing Demand for Biopharmaceuticals

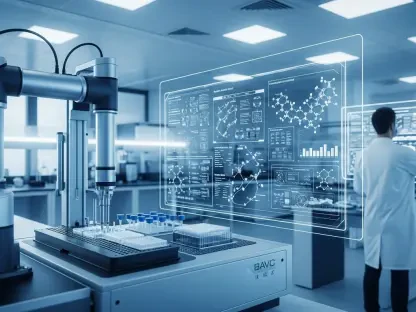

The growing demand for biopharmaceuticals in healthcare is a primary driver of the upstream bioprocessing market. Biopharmaceutical companies in the U.S. and the EU collectively raised 81.1 billion USD in 2023, underscoring the sector’s robust growth. The first quarter of 2024 saw 115 research and development partnerships amounting to 36 billion USD, emphasizing the industry’s focus on innovation. The adoption of single-use bioreactors and automation is enhancing production quality, driving efficiency, and controlling costs, aligning with the trend toward scalable and flexible manufacturing solutions.

These single-use bioreactors are particularly advantageous because they minimize contamination risks and reduce setup times, catering to the high demand for biopharmaceuticals. Automation also allows for real-time monitoring, which significantly improves overall production quality and cost management. Companies are investing heavily in these technologies to stay ahead in a competitive market, as they offer scalable solutions that can adapt to varying production needs. The combination of high demand and innovative technology is a significant factor propelling the upstream bioprocessing market’s rapid growth.

Advancements in Biologics Production

Advancements in biologics production are also fueling market growth. New technologies, such as artificial intelligence (AI) and advanced sensing, optimize processes through real-time monitoring capabilities. These innovations are crucial for developing more flexible production platforms, especially in the context of personalized medicine and biosimilars. Additionally, changes in policies for sustainable practices are shaping the course for long-term growth, aiming for a future with a lower environmental impact.

For instance, AI-driven analytics can predict and adjust to optimal production conditions, thereby enhancing yield and reducing waste. The integration of advanced sensing allows for continuous real-time monitoring, enabling immediate adjustments to ensure product quality and consistency. Furthermore, the shift toward sustainable practices is not merely regulatory but also market-driven, as companies recognize that environmentally friendly solutions can provide long-term cost savings and improve their public image. All these factors collectively influence the upward trajectory of the upstream bioprocessing market.

Major Players in the Market

Leading Companies Driving Innovation

Several major players are at the forefront of the upstream bioprocessing market, driving innovation and technological advancements. Companies such as Thermo Fisher Scientific, Inc., Merck KGaA, Corning Incorporated, Sartorius AG, and Eppendorf AG are developing new products and technologies that enhance upstream bioprocessing capabilities. These companies are instrumental in pushing the boundaries of what is possible in biopharmaceutical production.

These leading companies are not just focusing on product innovation; they are also heavily invested in research and development to find more efficient production methods. For instance, Merck KGaA is actively exploring cell and gene therapy innovations, aiming to streamline production and reduce costs. Similarly, Thermo Fisher Scientific is focusing on biobased solutions to minimize the environmental impact of manufacturing processes. Their contributions are setting new standards in the industry, making them crucial players in this rapidly growing market.

Strategic Partnerships and Collaborations

Strategic partnerships and collaborations are also pivotal in driving market growth. For instance, in August 2024, Merck KGaA acquired Mirus Bio to bolster its leadership in upstream bioprocessing and advance innovations in cell and gene therapy production. Such collaborations enable companies to leverage each other’s strengths, driving further innovation and efficiency in the market.

These partnerships often involve sharing technology, expertise, and intellectual property, which accelerates the development of new solutions. For example, the acquisition of Mirus Bio allows Merck KGaA to integrate cutting-edge technologies into its existing portfolio, thereby enhancing its overall capability in biologics production. Collaborations between firms also facilitate faster scaling of new technologies, ensuring that innovations reach the market quicker. This collaborative approach is a key factor contributing to the dynamism and rapid growth of the upstream bioprocessing market.

Market Segmentation and Analysis

Product Segmentation

The upstream bioprocessing market is divided into various product categories, including bioreactors/fermenters, cell culture products, filters, bioreactor accessories, bags and containers, and others. Each product category plays a crucial role in the bioprocessing workflow, contributing to the overall efficiency and quality of biopharmaceutical production.

Bioreactors and fermenters are essential for cultivating cells in a controlled environment, making them a cornerstone of bioprocessing. Cell culture products, including media and supplements, provide the necessary nutrients for cell growth. Filters ensure the purity of the bioproducts by removing contaminants, while bioreactor accessories enhance the functionality and efficiency of the production process. Bags and containers are crucial for the storage and transportation of bioproducts. Each of these product segments is vital for a smooth and efficient bioprocessing workflow, thereby supporting the industry’s expansion.

Workflow Segmentation

The workflow segment includes media preparation, cell culture, and cell separation. These workflows are essential for the successful production of biopharmaceuticals, with each step requiring precise control and optimization to ensure high-quality output. Advances in automation and real-time monitoring are enhancing these workflows, driving efficiency and reducing the risk of contamination.

Media preparation is the foundational step, ensuring that cells receive the required nutrients and environment for growth. Cell culture then involves growing these cells under controlled conditions, which is crucial for producing biopharmaceuticals. Cell separation is the final step, where the desired cells or products are isolated from the culture. Automation and real-time monitoring technologies are increasingly being integrated into these workflows, offering improved control and consistency in production. These technological advancements are pivotal in maintaining high standards of quality and efficiency in biopharmaceutical production.

Use Type Segmentation

The use type segment is categorized into multi-use and single-use systems. Multi-use systems lead the market, accounting for a 56% share in 2023, due to their well-established demand, proven technology, and scalability for large production volumes. However, single-use systems are expected to witness the fastest growth, with a CAGR of 16.35% from 2024 to 2032, thanks to their flexibility, reduced setup times, and lower risk of contamination.

Multi-use systems offer the advantage of being reusable, making them cost-effective for large-scale production. They are built to withstand rigorous cleaning and sterilization processes, ensuring long-term use. On the other hand, single-use systems are gaining popularity due to their convenience and flexibility. They minimize the risk of cross-contamination and require less time for setup and validation, making them ideal for smaller batches and personalized medicine. The growing preference for single-use systems is indicative of the market’s shift toward more adaptable and efficient production methods.

Mode Segmentation

The mode segment includes in-house and outsourced processes. The in-house segment dominated the market in 2023, with a 59% share, as it enables firms to maintain control over product quality, intellectual property, and process integration. The outsourced segment is predicted to grow at the fastest CAGR of 16.39% from 2024 to 2032, driven by higher demand for cost efficiency, flexibility, and specialized expertise.

In-house production allows companies to closely monitor and control every aspect of the bioprocessing workflow, ensuring that quality standards are met. It also enables firms to protect their intellectual property and integrate new technologies seamlessly into existing processes. On the other hand, outsourcing offers the advantage of tapping into specialized expertise and infrastructure without the need for significant capital investment. This is particularly appealing for smaller biotech firms or those looking to scale quickly. The trend toward outsourcing is expected to continue as companies seek to balance cost efficiency with the need for high-quality biopharmaceutical production.

Key Drivers

Advancements in Bioprocessing Technologies

Technological innovation continues to revolutionize the biopharma market with cutting-edge solutions, optimizing efficiency and scalability in biomanufacturing. These advancements are crucial for meeting the increasing demand for biopharmaceuticals, vaccines, and advanced therapies.

From AI-driven analytics to real-time monitoring systems, these technologies are enhancing every aspect of bioprocessing, making it more efficient and reliable. For example, advanced sensors can continuously monitor cell cultures, providing real-time data that allows for immediate adjustments in the production process. This not only improves yield but also reduces waste and operational costs. Furthermore, the development of more robust bioreactors and fermentation systems enables large-scale production without compromising quality. These technological advancements are key drivers in the current and future growth of the upstream bioprocessing market.

Emerging Biotech Companies

New biotech firms are fueling market growth through novel therapies and precision medicine. These companies are increasingly engaging in collaborations and partnerships, driving further innovation within the market. Their contributions are essential for the continued expansion and evolution of the upstream bioprocessing market.

Emerging biotech companies bring fresh perspectives and innovative approaches to biopharmaceutical production. They often focus on niche markets and novel therapies that address unmet medical needs. By engaging in strategic partnerships with established industry players, these companies can accelerate the development and commercialization of their products. These collaborations also provide access to advanced technologies and expertise, further driving innovation. As a result, emerging biotech firms are playing a pivotal role in shaping the future of the upstream bioprocessing market.

Regional Analysis

North America

North America dominated the upstream bioprocessing market in 2023, capturing a significant share of the market. The region’s strong demand for biopharmaceuticals, supported by leading industry players and solid infrastructures, has bolstered its market position. Favorable regulations, advanced manufacturing capabilities, and cutting-edge technologies contribute to North America’s competitive edge, ensuring sustained investments and market leadership.

The presence of major biopharmaceutical companies in North America, particularly in the U.S., facilitates a robust ecosystem for upstream bioprocessing. The region benefits from a well-established infrastructure that supports research, development, and large-scale production. Additionally, favorable government policies and funding for biotech research and innovation further enhance North America’s market position. The region’s ongoing investment in advanced technologies and sustainable practices ensures its continued dominance in the upstream bioprocessing market.

Asia Pacific

The Asia Pacific region is projected to grow at the fastest CAGR of 17.74% from 2024 to 2032. The region is benefiting from large investments, surging healthcare needs, and government support for biotechnology. Asia Pacific’s developing capabilities in contract manufacturing and its increasing share of the global biopharma market are reshaping production strategies and attracting investment alternatives.

Countries like China and India are emerging as significant players in the biopharmaceutical industry, supported by substantial government investments and policy incentives. The region’s growing expertise in contract manufacturing attracts global companies looking for cost-effective production solutions. Additionally, the rising demand for healthcare services in Asia Pacific, driven by an increasing population and higher incidence of chronic diseases, is boosting the need for biopharmaceuticals. The confluence of these factors is positioning the Asia Pacific region as a crucial growth market for upstream bioprocessing.

Innovations and Sustainable Practices

Innovation is a key theme within the upstream bioprocessing market. For example, in 2024, Thermo Fisher Scientific launched biobased solutions, including sustainable single-use containers, to reduce the climate impact of biologics manufacturing while maintaining product performance. In August 2024, Merck KGaA acquired Mirus Bio to bolster its leadership in upstream bioprocessing and advance innovations in cell and gene therapy production. Sustainable practices and technological advancements are integral aspects of these innovative strategies.

Companies are increasingly focusing on sustainability in their operations, recognizing the importance of reducing their environmental footprint. This includes the development of biobased and biodegradable materials for single-use systems, as well as energy-efficient production processes. Furthermore, the integration of AI and advanced sensors not only improves efficiency but also minimizes waste, contributing to more sustainable bioprocessing practices. These innovations are crucial for the industry’s long-term growth and its ability to meet the rising demand for biopharmaceuticals while minimizing environmental impact.

Conclusion

The upstream bioprocessing market is witnessing remarkable growth, fueled by a combination of factors that are transforming the biopharmaceutical production landscape. With a valuation of $22.79 billion in 2023, this market is anticipated to skyrocket to $82.10 billion by 2032. This represents a robust compound annual growth rate (CAGR) of 15.35% from 2024 to 2032.

Key drivers behind this impressive expansion include technological advancements, innovation, and a growing demand for flexibility in production processes. Innovation is playing a crucial role, as companies are constantly seeking new methods to streamline operations, reduce costs, and heighten efficiency. Advanced technologies are being integrated into the bioprocessing workflows, enhancing productivity and enabling scalable models suited for diverse therapeutic needs.

Moreover, the flexibility offered by modern upstream bioprocessing techniques allows for quicker adaptations to changes in production requirements and regulatory landscapes. This adaptability is particularly significant in the biopharmaceutical sector, where rapid response to market demands and compliance standards is essential.

As we move forward, the thriving upstream bioprocessing market is expected to increasingly rely on cutting-edge technologies and innovative strategies. These factors not only support the sector’s growth but also promise substantial advancements in biopharmaceutical development and production, ultimately improving global healthcare outcomes.