A significant obstacle preventing cultivated meat from becoming a staple in grocery stores has been the challenge of creating affordable, complex structures that mimic the texture and composition of traditional cuts like steak or chops. Researchers at University College London have unveiled a novel solution that addresses this very issue, developing an innovative method that could fundamentally alter the economics of lab-grown meat. A team led by doctoral student Christian Harrison has successfully transformed spent brewer’s yeast, a massive and often discarded byproduct of the beer industry, into a viable and food-safe scaffold for growing meat cells. This breakthrough in upcycling not only offers a sustainable use for an industrial waste stream but also presents a low-cost alternative to the expensive materials that have hindered the commercialization of structured cultivated meat, potentially paving the way for its wider acceptance and availability.

From Brewery Waste to an Edible Framework

The foundation of this research is a clever application of upcycling, where one industry’s waste becomes a valuable raw material for another. Annually, breweries generate immense quantities of yeast slurry, a nutrient-dense byproduct left over after fermentation. Instead of treating this as waste, the UCL scientists harnessed its potential by introducing a specific bacterium, Komagataeibacter xylinus, to the slurry. This microbe consumes the residual sugars, proteins, and minerals present in the yeast and, through a natural biological process, synthesizes a durable, edible biopolymer known as bacterial cellulose. This resulting material is chemically identical to the glucose-based fiber network found in the popular food product nata de coco. A key advantage of this microbial production method is that the cellulose is naturally free of lignin, a rigid polymer found in plants, which allows it to achieve a high degree of purity essential for food-grade applications and sets it apart from plant-derived alternatives.

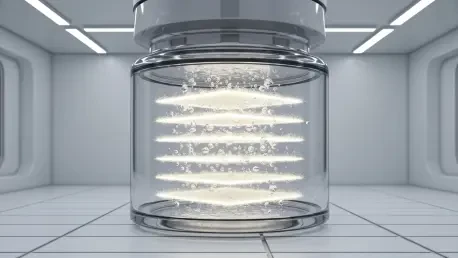

To replicate the fibrous and layered nature of animal muscle, the research team constructed prototypes by stacking multiple thin sheets of the newly created bacterial cellulose and binding them together with a plant-based gel. This layering technique proved to be a critical design choice, offering precise control over the final thickness of the scaffold while ensuring that air and essential nutrients could effectively permeate the entire structure. This is vital for the survival of cells deep within the tissue, a common challenge in tissue engineering. The physical properties of the scaffold were then evaluated using texture profile analysis, a standard industry method that compresses a sample to measure characteristics like hardness and chewiness. The results showed that the cellulose scaffold was notably less hard than typical test samples, an encouraging finding that suggests it could help replicate the complex and sought-after “mouthfeel” of conventional meat, which remains one of the most significant hurdles for consumer acceptance in the cultivated meat sector.

Cultivating Cells and Facing Biological Hurdles

The scaffold’s ability to support living cells was confirmed through a series of promising, albeit preliminary, experiments. When seeded with fibroblasts, the connective-tissue cells responsible for building the structural framework of meat, the scaffold demonstrated its fundamental biocompatibility. Within the first 24 hours, approximately 36 percent of these cells successfully attached themselves to the cellulose material, and subsequent cell counts showed a continued increase over a 72-hour period. This initial success indicates the material’s potential as a viable substrate for the first phase of cell growth. However, the research also clearly identified a crucial area for improvement. In controlled comparisons, standard plastic plates used in laboratory settings supported a higher number of cells, suggesting that the surface of the cellulose scaffold requires further optimization or “tuning” to enhance the rates of cell attachment and proliferation, a necessary step to maximize tissue density and efficiency in a production environment.

Beyond simple cell attachment, the ultimate goal of replicating conventional meat requires a more complex biological approach that the current technology has yet to achieve. To truly mimic the sensory experience of eating meat, a scaffold must host a co-culture of both muscle and fat cells. The intricate interplay between these two cell types is what creates the characteristic flavor, aroma, and lubrication during the cooking process, attributes that are essential for a convincing final product. Until this mixed-tissue growth can be successfully and consistently achieved, the technology remains better suited for producing less complex items like cultivated ground meat rather than highly structured, whole-cut products. This limitation underscores the significant biological engineering challenges that lie ahead in moving from a basic cellular support structure to a fully realized, multi-tissue meat analogue that can compete with traditional animal products in both taste and texture.

Navigating Industrial and Environmental Realities

The transition of this innovative technology from a controlled laboratory setting to a full-scale industrial process is fraught with significant challenges. A primary concern is the inherent variability of the raw material itself. Different beer recipes and brewing techniques result in spent yeast with fluctuating nutritional compositions. The UCL team observed that changes in certain salt metabolites within the yeast could negatively impact the final cellulose yield. In a commercial setting, this would necessitate costly measures such as continuous monitoring, the blending of different waste batches, or even recipe adjustments to ensure a consistent and reliable output. Furthermore, food safety and regulatory compliance present another formidable hurdle. The bacterial cellulose must be meticulously cleaned—a process the team accomplished with an alkaline solution—to remove any residual bacteria or yeast. This cleaning process must be finely balanced, as overly harsh methods could degrade the scaffold’s delicate porosity and soft structure, compromising its effectiveness. Developers will be required to conduct exhaustive safety testing to meet the stringent standards of food-grade materials, a process complicated by sourcing waste from a multitude of different breweries.

The broader economic and environmental context in which this technology exists ultimately dictated its viability. While cultivated meat was often positioned as a sustainable alternative to traditional livestock, which accounts for approximately 14.5 percent of anthropogenic greenhouse gas emissions, its own environmental footprint was not guaranteed to be superior. The climate impact of its production depended heavily on the energy source used; facilities powered by fossil fuel-heavy electrical grids could have had a greater long-term warming effect than even conventional beef production, necessitating a full life cycle assessment to verify any green claims. Economically, the entire supply chain—from sourcing brewery waste to large-scale cellulose production in bioreactors and coordinating logistics—hinged on the availability of cheap, and preferably renewable, energy. Before this technology ever reached the market, the entire process, including the novel scaffold, had to undergo a rigorous and lengthy review from regulatory bodies like the U.S. FDA and USDA, which oversaw everything from the cell lines used to final processing and labeling, highlighting the long road ahead.