The Industrial Internet of Things (IIoT) is revolutionizing biomanufacturing, a crucial element of the broader movement toward Industry 4.0. By leveraging the power of interconnected devices and systems, bioprocessing facilities are experiencing a surge in productivity and operational efficiency. Technologies such as real-time data monitoring and predictive analytics are now indispensable tools in the sector, facilitating proactive operational management. This technological evolution is paramount in minimizing human errors and ensuring strict adherence to stringent healthcare regulations. The IIoT enables better decision-making, based on accurate and timely data, and helps maintain the delicate balance between quality and efficiency in biomanufacturing environments. These advancements underscore how critical digital transformation is for the future of biomanufacturing, ensuring that the sector can meet the growing demands of healthcare provision while remaining compliant and competitive.

Opportunities for Optimization

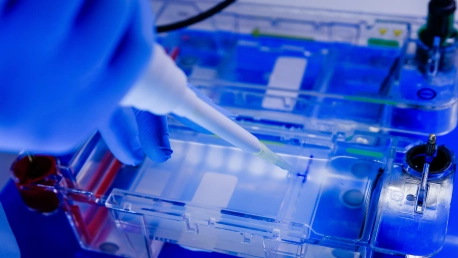

Enhanced Process Control

The integration of the Industrial Internet of Things (IIoT) into biomanufacturing is transforming process control. Smart, interconnected devices deliver precise data in real-time about vital process parameters, allowing operators to implement adjustments quickly and with precision. This streamlines bioprocessing by reducing variation, ensuring product quality consistently meets rigorous standards. IIoT’s advanced systems enable tighter control loops, a critical aspect for quality maintenance. This evolution is significant, propelling the biomanufacturing sector from a traditionally reactive stance to one that is decidedly proactive in managing processes. With IIoT, biomanufacturers can now anticipate and mitigate potential process disruptions before they occur, improving efficiency and reliability. This technological leap in monitoring and control heralds a new era of sophistication in biomanufacturing.

Predictive Maintenance and Analytics

The Industrial Internet of Things (IIoT) has transformed biomanufacturing with its predictive maintenance capabilities. This innovation involves embedding sensors in equipment to detect early signs of deterioration, allowing for maintenance planning before any major system failures occur. As these sensors collect data, predictive analytics tools process this information, identifying trends that could lead to system optimizations. Such data-driven insights help companies to proactively manage their machinery, reducing unexpected downtime, maximizing operational efficiency, and ensuring consistent product quality. The strategic integration of IIoT in biomanufacturing not only enhances the reliability of production processes but also provides a competitive edge by ensuring continuous production flows, a critical factor in this fast-paced industry.

Navigating Regulatory and Technical Challenges

Data Integrity and Compliance

The Industrial Internet of Things (IIoT) opens up vast opportunities for advancements, especially in the biopharmaceutical industry. Yet, these advancements carry significant challenges, particularly within data security and regulatory compliance. Accuracy, verification, and protection of data are crucial in this highly regulated sector. As IIoT integrates into biopharmaceutical operations, stringent efforts must be made to maintain data integrity. This involves creating an infrastructure that not only reliably secures sensitive data but also adapts to evolving compliance mandates. IIoT implementation, therefore, necessitates a resilient framework that operates with precision and safeguards against unauthorized data breaches, adhering to stringent industry standards and regulatory requirements. Ensuring that privacy and integrity are not compromised is vital for the legitimacy and success of IIoT solutions in the nuanced and controlled environments of biopharma.

Technical Hurdles in Implementation

Modernizing traditional biomanufacturing facilities with the Industrial Internet of Things (IIoT) presents significant challenges. Retrofitting old systems to integrate a full suite of monitoring sensors is not straightforward. These older setups often weren’t designed for digital connectivity, making the task even more complex. Moreover, many vital bioprocess parameters cannot be measured directly, necessitating advanced algorithms and big data tools to interpret indirect measurements.Despite these obstacles, the shift toward IIoT-enabled biomanufacturing is critical. It promises enhanced efficiency, reliability, and intelligence in bioprocess control. Careful implementation is essential to navigate the intricate web of technical demands and regulatory considerations. By successfully integrating IIoT, biomanufacturing can lead the industrial sector into a new era of innovation and productivity, exemplifying the potential of Industry 4.0.