I’m thrilled to sit down with Ivan Kairatov, a seasoned biopharma expert with a wealth of experience in research and development. With a sharp focus on technology and innovation, Ivan has been at the forefront of advancing biologics formulation, particularly in tackling the complex challenges of stability under mechanical stress. Today, we’ll dive into his insights on developing scale-down agitation models for early-stage biologics, exploring how these models simulate real-world stresses, the impact on drug quality, and the strategies to ensure stable, effective formulations.

Can you tell us about your role in the biopharma industry and what drives your passion for biologics development?

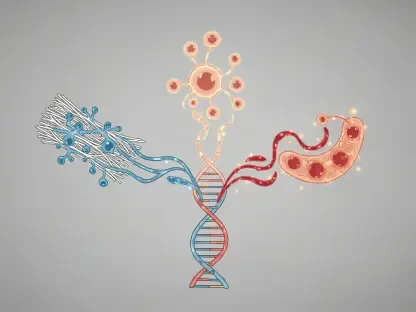

Thanks for having me. I’ve spent years working in research and development within the biopharma space, focusing on injectable drug products, particularly biologics like high-concentration monoclonal antibodies. My role often involves designing and testing formulations to ensure they remain stable and effective under various conditions. What drives me is the challenge of solving complex problems—biologics are incredibly sensitive molecules, and ensuring their integrity from manufacturing to patient administration is both a scientific puzzle and a meaningful mission to improve patient outcomes.

What drew you to specialize in the formulation of biologics, especially under challenging conditions like mechanical stress?

Early in my career, I was fascinated by how delicate proteins are and how easily their structure can be disrupted by external forces. Biologics, unlike small-molecule drugs, have a unique complexity that makes them prone to issues like aggregation. I saw an opportunity to make a real impact by focusing on mechanical stress—something inevitable during manufacturing or shipping—and developing ways to predict and mitigate those effects. It’s rewarding to work on something that directly ties to drug quality and patient safety.

Can you explain what a scale-down agitation model is and why it plays such a critical role in biologics development?

Absolutely. A scale-down agitation model is essentially a lab-based system that mimics the mechanical stresses a biologic drug might face in the real world, but on a smaller, controlled scale. Think of it as a way to simulate shaking, mixing, or vibrations that occur during manufacturing, transport, or even administration. These models are crucial because they allow us to study how a drug product holds up under stress early in development, helping us identify potential stability issues before they become costly problems down the line.

What types of mechanical stresses do biologics typically encounter throughout their lifecycle?

Biologics face a variety of mechanical stresses from the moment they’re manufactured. During production, there’s mixing and pumping that can introduce shear forces. Then, during transportation, drugs might be subjected to constant shaking or vibrations, especially if shipped over long distances. Even storage conditions or the act of administration—say, through a syringe—can add stress. Each of these can potentially degrade the protein structure, so understanding and preparing for them is vital.

How does agitation stress specifically impact the quality of a biologic drug product?

Agitation stress, like shaking or mixing, can have a profound effect on biologics. It often exposes hydrophobic regions of the protein, which can lead to clumping or aggregation. It can also cause the protein to unfold, losing its intended shape and, consequently, its function. These changes directly affect the drug’s quality—reducing its potency or creating particles that could pose safety risks. So, agitation isn’t just a minor nuisance; it’s a major factor in ensuring a drug remains effective and safe.

Can you elaborate on how protein aggregation occurs under agitation and why it’s such a concern for drug potency?

Certainly. When a biologic is agitated, the physical motion can disrupt the protein’s delicate structure, exposing parts that are normally tucked away. These exposed regions, often hydrophobic, attract other protein molecules, causing them to stick together and form aggregates. This is a big concern because aggregated proteins often lose their biological activity—they can’t bind to their target as intended, which means the drug’s potency drops. Beyond that, aggregates can trigger other issues, like immune responses in patients, making this a critical area to address.

What are the potential risks tied to particulate formation in biologics, especially from a safety or regulatory perspective?

Particulate formation, which often stems from aggregation, is a serious issue. These particles, even if subvisible, can increase the risk of immunogenicity—meaning they might provoke an unwanted immune response in patients, potentially leading to adverse effects. From a regulatory standpoint, there are strict guidelines on acceptable levels of particulates in injectable drugs because of these safety concerns. If a drug product doesn’t meet those standards, it can face delays or rejection during approval, so controlling particulate formation is non-negotiable.

How does a scale-down agitation model help in understanding and managing the effects of mechanical stress on biologics?

The beauty of a scale-down agitation model is that it lets us replicate real-world stresses in a controlled environment. By subjecting small volumes of a biologic to conditions like shaking or vibration, we can observe how the drug responds—whether it forms aggregates, develops particles, or loses potency. This insight is invaluable for tweaking formulations early on, allowing us to add stabilizers or adjust conditions to enhance stability before scaling up to full production.

What are the primary goals when using such a model during early-stage formulation development?

In the early stages, our main goals are to identify potential weak points in a formulation and build a foundation for stability. We’re looking to understand how the biologic behaves under stress, which quality attributes—like purity or particle levels—are most affected, and how we can optimize the formulation to withstand those challenges. Ultimately, it’s about de-risking the development process, ensuring we don’t invest in a formulation that fails under real-world conditions later on.

What specific quality attributes do you focus on when testing biologics after agitation stress, and why do they matter?

After exposing biologics to agitation, we evaluate several key quality attributes. These include the drug’s appearance and turbidity, which can indicate visible degradation or cloudiness. We also look at the formation of high molecular-weight species, which are essentially aggregates, as well as subvisible particles that might not be seen by the naked eye but can still pose risks. Additionally, we assess size or charge variations in the protein structure. These attributes matter because they directly correlate to the drug’s safety, efficacy, and compliance with regulatory standards.

What analytical techniques do you rely on to measure changes in these quality attributes after stress testing?

We use a range of sophisticated tools to get a clear picture of the drug’s condition post-stress. For instance, size-exclusion ultra-performance liquid chromatography helps us detect high molecular-weight species, giving us insight into aggregation levels. Micro flow imaging is great for spotting subvisible particles, while optical density measurements help assess turbidity. Each method provides a piece of the puzzle, allowing us to comprehensively evaluate how agitation impacts the drug product.

In your work, you’ve explored different agitation methods like orbital shakers and vortexers. How do these tools differ in the type of stress they apply to samples?

Each agitation method creates a unique stress profile. An orbital shaker, for example, generates a consistent, circular motion that mimics broader, repetitive shaking—like what might happen during transport. A vortexer, on the other hand, creates intense, rapid vibrations, stressing the sample in a more localized, aggressive way. These differences allow us to simulate a spectrum of real-world conditions and understand how various stresses uniquely affect the biologic.

What challenges have you encountered while developing or refining agitation models for early-stage testing?

One of the biggest challenges is balancing realism with practicality. Early in development, we often have limited material to work with, so we need models that use small volumes but still accurately reflect large-scale conditions. Additionally, ensuring consistency across tests—things like vial positioning or duration of agitation—can be tricky but is essential for reliable data. There’s also the challenge of interpreting results, as different biologics react differently to stress, so we’re constantly adapting our approach.

Looking ahead, what is your forecast for the future of agitation stress testing in biologics development?

I’m optimistic about where this field is headed. I think we’ll see more advanced, automated systems for stress testing that can simulate a wider range of real-world conditions with even greater precision. There’s also potential for integrating digital tools, like predictive modeling, to anticipate stability issues before physical testing. As biologics become more complex, especially with novel formats, I believe agitation models will evolve to be more tailored, helping us ensure drug quality and patient safety in increasingly innovative ways.