I’m thrilled to sit down with Ivan Kairatov, a renowned biopharma expert whose extensive experience in research, development, and innovation has positioned him as a thought leader in the cell and gene therapy (CGT) industry. With a sharp focus on emerging technologies and strategic growth, Ivan offers unique insights into the future of this rapidly evolving field. In our conversation, we explore a visionary framework for CGT development, diving into personalized treatments, direct-to-patient therapies, scalable off-the-shelf solutions, and the critical balance of innovation with cost and quality. Join us as we unpack the strategies that could shape the next era of biopharmaceutical advancements.

How did you develop the concept of a ‘three product focus’ for the future of cell and gene therapy, and what does it entail?

The ‘three product focus’ came from observing the diverse needs and challenges in CGT and recognizing that no single approach can address everything. It breaks down into autologous therapies, which are personalized for each patient; in-vivo therapies, where genetic material is delivered directly into the body; and allogeneic therapies, often called off-the-shelf solutions, made from donor cells or stem cells. I developed this framework by analyzing where the science is strongest and where the industry struggles most with scalability and access. It’s about creating a roadmap for developers to prioritize innovation in areas that can drive both clinical impact and sustainable growth.

Why do you believe these three areas are pivotal to the industry’s growth?

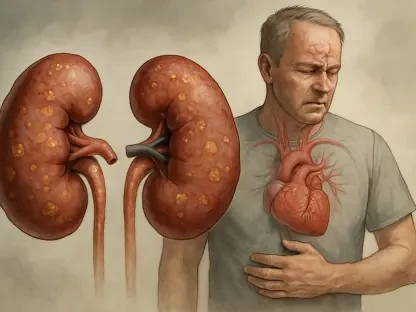

Each area tackles a unique piece of the puzzle. Autologous therapies are the gold standard for personalized medicine, offering tailored solutions for complex diseases like cancer. In-vivo therapies push the boundaries of how we can treat conditions at a genetic level without needing to extract and modify cells outside the body. Allogeneic therapies, on the other hand, promise scalability and accessibility, potentially making treatments more affordable and widely available. Together, they address the spectrum of patient needs, from highly specific to broadly applicable, while also aligning with the industry’s need for viable business models.

Let’s dive into autologous therapies. What makes them such a cornerstone of personalized medicine?

Autologous therapies are unique because they use a patient’s own cells, which minimizes the risk of rejection and maximizes compatibility. Think of treatments like CAR-T cell therapy for blood cancers—these are custom-made for each individual based on their specific biology. This personalization allows us to target diseases with incredible precision, often achieving outcomes that weren’t possible with traditional drugs. It’s a game-changer for patients with conditions that don’t respond to standard care.

How does automation play a role in enhancing the efficiency of autologous therapies?

Automation is critical because producing autologous therapies is labor-intensive and prone to human error. By integrating automated systems, we can standardize processes like cell collection, modification, and expansion. This not only speeds up production but also ensures consistency across batches. It reduces costs and makes it feasible to treat more patients without sacrificing quality, which is a huge hurdle when every treatment is essentially a one-off.

Can you explain what closed-system manufacturing means for autologous treatments and why it’s important?

Closed-system manufacturing refers to a setup where the entire process of cell handling and modification happens in a sealed, sterile environment. This minimizes contamination risks and reduces the need for highly specialized clean rooms, which are expensive to maintain. For autologous therapies, where each batch is unique to a patient, this approach is vital—it ensures safety and quality while also making production more manageable, especially when you’re working close to the point of care.

Speaking of proximity, how does bringing manufacturing closer to the patient impact outcomes?

When manufacturing happens near the patient, it cuts down on the time and logistics of transporting sensitive biological materials. For autologous therapies, where cells are often time-sensitive, this can mean the difference between a viable treatment and one that’s degraded. It also allows for faster turnaround, so patients get their therapy sooner, which can be critical in life-threatening conditions. Plus, it fosters better collaboration between clinicians and manufacturers, tailoring the process even more closely to the patient’s needs.

Shifting to in-vivo therapies, can you walk us through what they are and how they differ in approach?

In-vivo therapies involve delivering genetic material directly into a patient’s body, often using a vector like a virus to carry the therapeutic genes to the target cells. Unlike autologous therapies, there’s no need to extract cells, modify them outside the body, and reinfuse them. This approach is particularly promising for genetic disorders where you need to correct a mutation across a wide range of cells or tissues. It’s a more direct method, but it comes with its own set of challenges in ensuring the therapy reaches the right place and works safely.

What are some of the biggest hurdles in delivering genetic material directly to patients with in-vivo therapies?

The main challenge is precision—getting the genetic material to the exact cells or tissues you’re targeting without affecting others. There’s also the issue of safety; some delivery vectors, like viruses, can trigger immune responses or cause unintended side effects. Then you’ve got payload capacity—how much genetic material can you actually deliver? Overcoming these hurdles requires innovation in vector design and a deep understanding of how different tissues respond to these therapies.

You’ve talked about improving specificity and safety in delivery mechanisms. Can you share an example of how that’s being achieved?

Absolutely. One exciting development is the engineering of viral vectors to be more selective. For instance, scientists are modifying adeno-associated viruses (AAVs) to target specific cell types, like liver cells for certain genetic disorders, while avoiding others. This reduces off-target effects and lowers the risk of toxicity. Additionally, advances in imaging and diagnostics help us track where the therapy goes in real-time, allowing for adjustments during treatment. It’s about making the delivery as precise as a surgical tool.

What alternatives to viral vectors are emerging, and why are they gaining traction?

Non-viral vectors, like lipid nanoparticles, are getting a lot of attention. They’re often safer because they don’t provoke the same immune responses as viruses, and they’re easier to produce at scale. They’ve already shown success in mRNA vaccines, and now they’re being adapted for gene therapy to deliver DNA or RNA. While they may not yet match the efficiency of viral vectors in some applications, their flexibility and lower risk profile make them a promising option for the future.

Turning to allogeneic therapies, what sets these ‘off-the-shelf’ treatments apart from the other types?

Allogeneic therapies are made from donor cells or stem cells, rather than the patient’s own, which means they can be produced in large batches and stored until needed. Unlike autologous therapies, which are bespoke, these are ready-to-use, making them more like traditional drugs in terms of distribution. This scalability is their biggest strength—they have the potential to treat many patients from a single production run, which could dramatically lower costs and increase access.

How can allogeneic therapies become more cost-effective compared to personalized treatments?

The key is economies of scale. Since allogeneic therapies aren’t tailored to each patient, you can manufacture them in bulk, reducing the per-unit cost. Streamlining production processes and optimizing storage also help cut expenses. Over time, as we refine cell engineering and sourcing—like using standardized donor cells or stem cell lines—these therapies could approach the cost structure of conventional biologics, making them a more viable option for widespread use.

What role do induced pluripotent stem cells (IPSCs) play in advancing allogeneic therapies?

IPSCs are a game-changer because they can be derived from adult cells and reprogrammed into a pluripotent state, meaning they can turn into almost any cell type. For allogeneic therapies, this offers a consistent, renewable source of cells that can be engineered for specific treatments. IPSCs allow us to create standardized cell banks, which can be used to produce therapies at scale. They also reduce reliance on donor variability, improving consistency and reliability across batches.

How do you envision allogeneic therapies reaching the reliability of traditional biologics?

It’s about refining the science and the process. We need to perfect cell engineering to ensure these therapies are as predictable and safe as biologics, minimizing risks like immune rejection. Advances in gene editing can help by making the cells less likely to trigger adverse reactions. On the manufacturing side, adopting rigorous quality controls and standardized protocols will build trust in their consistency. Over time, as clinical data accumulates, I believe allogeneic therapies will become a staple in healthcare, much like monoclonal antibodies are today.

You’ve highlighted optimizing the value proposition in CGT. Can you explain what that means in practical terms?

Optimizing the value proposition is about ensuring that these therapies deliver on three fronts: cost-effectiveness, quality, and convenience. It’s not enough to have groundbreaking science or impressive clinical results if the treatment is prohibitively expensive or hard to administer. Practically, it means designing therapies that can be produced affordably, maintain high safety and efficacy standards, and fit seamlessly into healthcare systems so patients and providers can access them without unnecessary hurdles.

What does cost-effectiveness look like when it comes to cell and gene therapies?

Cost-effectiveness in CGT means balancing the upfront investment in development and production with long-term value for patients and payers. These therapies often target rare or severe diseases with few alternatives, so they can justify higher initial costs if they deliver durable, life-changing outcomes—like a one-time treatment that cures a condition. But to be truly cost-effective, we need to reduce manufacturing expenses through innovation and scale, and work with healthcare systems to create payment models that spread costs over time.

How do you ensure high quality while also managing to keep costs under control?

It’s a tightrope, but it starts with robust process design—standardizing as much as possible without compromising the therapy’s integrity. Using automation and closed systems helps maintain quality by reducing variability and contamination risks, while also cutting labor costs. Rigorous testing at every stage ensures we catch issues early, avoiding expensive setbacks. Ultimately, quality and cost control go hand-in-hand when you invest in scalable, repeatable processes from the outset.

What makes a CGT therapy convenient for patients and healthcare providers to use?

Convenience comes down to simplifying the entire journey—from production to administration. For patients, it means therapies that require fewer hospital visits or less invasive procedures. For providers, it’s about having treatments that are easy to store, handle, and deliver without needing highly specialized training or infrastructure. Designing therapies with end-users in mind—like off-the-shelf products that don’t need complex customization—can make a huge difference in how widely they’re adopted.

As a leader in this space, how do you see investors and developers balancing the push for innovation with the need for sustainability in CGT?

It’s a delicate balance. Investors are drawn to the transformative potential of CGT, but they’re also wary of the high risks and long timelines to profitability. Developers need to focus on innovations that not only push scientific boundaries but also address real-world challenges like cost and access. Sustainability comes from building partnerships across the ecosystem—academia, industry, and regulators—to share risks and resources. It’s also about prioritizing projects with clear paths to market, ensuring that innovation translates into tangible benefits rather than just experimental breakthroughs.

What’s your forecast for the future of cell and gene therapy over the next decade?

I’m optimistic. I believe we’ll see a convergence of these three product types—autologous, in-vivo, and allogeneic—becoming more integrated and complementary. Advances in gene editing, delivery systems, and manufacturing will drive down costs and improve outcomes, making these therapies accessible to a broader range of patients and conditions. We’ll likely see regulatory frameworks evolve to keep pace with innovation, fostering faster approvals without compromising safety. Ultimately, I think CGT will move from being a niche, high-cost option to a mainstream pillar of medicine, fundamentally changing how we treat some of the most challenging diseases.