The biopharmaceutical industry finds itself at a crossroads as the ever-increasing global demand for pharmaceuticals necessitates a reevaluation of traditional manufacturing approaches. With escalating costs and inefficiencies hindering timely drug production, the sector is turning towards a transformative strategy known as process intensification (PI). This innovative approach seeks to optimize bioprocessing techniques, aiming to enhance productivity, reduce operational costs, and accelerate drug development timelines. As competition intensifies in the global market, biopharmaceutical companies must adapt to ensure they can deliver affordable, high-quality medications to a growing population in need. PI appears to be the key to unlocking the potential for more efficient and cost-effective production.

Optimizing Bioprocessing for Efficiency and Innovation

At the heart of process intensification lies the fundamental goal of optimizing bioprocessing, tackling inefficiencies that have long plagued the sector. By leveraging advanced technologies and novel methodologies, manufacturers can significantly improve productivity and reduce costs. One of the most noteworthy shifts is towards intensified upstream processes, which have become especially relevant given the increasing interest in viral vectors for gene therapies and vaccinations, supplementing the traditional focus on monoclonal antibodies (mAbs). This trend reflects a broader movement within the industry to pioneer new methods that can streamline the production pipeline of such critical treatments.

The integration of continuous processing methodologies, such as perfusion cell culture, exemplifies the industry’s commitment to innovation. Instead of relying on conventional batch processes, these methods enable a constant production flow, minimizing downtime and enhancing efficiency. This advancement allows for greater scalability and adaptability, as manufacturers can adjust production rates in response to fluctuating demands. This flexibility is of paramount importance as it positions companies to meet not only current market requirements but also future challenges associated with emerging therapies and evolving regulatory landscapes.

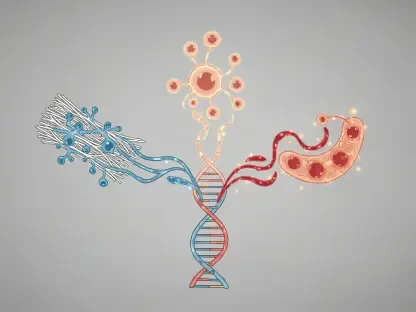

Adapting to New Modalities and Scaling Challenges

As biopharmaceutical companies strive to remain at the forefront of technological innovation, the adoption of PI technologies across various modalities and scales has become crucial. This process involves transitioning from traditional bioprocessing methods to more contemporary and versatile systems. Such adaptations are pivotal in achieving significant gains in economic efficiency, productivity, and sustainability. The shift towards intensified processes not only boosts upstream productivity by achieving higher cell densities but also allows for the use of smaller, modern bioreactors. These advanced bioreactors deliver throughput levels that can match or even exceed those of large traditional systems.

The benefits of adapting PI technologies extend beyond immediate gains in productivity and cost efficiency. Such approaches also contribute to sustainable manufacturing practices by reducing waste and energy consumption. In doing so, they align with environmental targets and regulatory mandates aimed at greener operations. As the call for sustainable industrial practices becomes increasingly pronounced, the implementation of PI represents not only an economic advantage but also an environmental imperative.

The Role of High-Density Cell Banks

High-density cell banks (HD) play a pivotal role in the strategy of process intensification, providing an innovative solution to simplifying and streamlining the drug development process. This approach involves utilizing high cell densities and functional cell banks to accelerate timelines. By starting with a higher initial cell mass, manufacturers can drastically reduce the time needed to cultivate sufficient biomass for seeding bioreactors. This acceleration compresses production schedules and supports the rapid development of new treatments.

Moreover, the simplification of seed train steps through HD cell banking offers a strategic advantage in operational efficiency. Fewer expansion phases mean a reduced risk of contamination, which ensures the high quality and reliability of biopharmaceutical products. The reduction in capital expenditures associated with these streamlined processes further exemplifies the advantages of adopting high-density cell banks. As technology evolves, this strategy is set to play an increasingly essential role in optimizing facility space utilization while simultaneously driving down costs.

Embracing Modular and Single-Use Technologies

The implementation of modular and single-use technologies signifies a profound shift in the way biopharmaceuticals are manufactured, offering unparalleled flexibility and efficiency. These systems enable manufacturers to easily scale production to accommodate varying volumes, reducing the risks of contamination and expediting turnaround times. By eliminating washing and sterilization processes, single-use systems streamline operations and enhance the overall speed of production.

Modular systems, by design, allow for swift modifications to manufacturing lines based on specific product requirements. This ease of transition between different bioprocessing tasks exemplifies the adaptability of modular configurations. The introduction of automated filling systems for single-use bags illustrates how these technologies standardize process stages and improve reproducibility while mitigating risks linked to manual handling. The combination of modular and single-use technologies provides a comprehensive approach to achieving seamless and efficient production workflows in the biopharmaceutical sector.

Transformative Impact of Automation and Continuous Processing

Automation represents another key pillar in the ongoing transformation of biopharmaceutical manufacturing. Advanced automated technologies, particularly in fluid and cold chain management, have revolutionized the handling, storage, and transportation of large volumes of materials. Automation enhances accuracy, traceability, and productivity, ensuring high precision in fill quantities and consistent processes. Additionally, automated cold chain procedures uphold regulatory compliance and quality standards while reducing the risk of errors and contamination associated with manual handling.

Continuous bioprocessing has emerged as a critical component of PI, substantially contrasting with traditional batch processing. Conducting production operations seamlessly without interruption offers numerous benefits, such as improved cell densities, consistent product quality, and reduced facility footprints. The ability of single-use technologies to facilitate continuous upstream expansion processes further underscores the adaptability they afford contract manufacturing organizations (CMOs) and contract development and manufacturing organizations (CDMOs). This adaptability enables the production of multiple products while maintaining high flexibility.

Bridging the Gap to Future Biopharmaceutical Needs

At the core of process intensification is the essential aim of optimizing bioprocessing by addressing longstanding inefficiencies. The use of advanced technologies and innovative approaches allows manufacturers to substantially boost productivity and cut costs. A significant transition is observed towards intensified upstream processes, notably as interest grows in viral vectors for gene therapies and vaccines, alongside the traditional monoclonal antibodies (mAbs) focus. This trend highlights a broader industry movement to innovate and streamline the production of vital treatments.

Integrating continuous processing methods, like perfusion cell culture, shows the sector’s dedication to progress. Rather than traditional batch processes, these techniques offer a continual production flow, reducing downtime and increasing efficiency. Such innovation enables improved scalability and flexibility, allowing manufacturers to modulate production rates according to demand fluctuations. This adaptability is crucial, equipping companies to meet current market needs and future challenges posed by emerging therapies and shifting regulatory requirements.