Ivan Kairatov, a renowned expert in biopharma, is at the forefront of innovation in the biotechnology and biomanufacturing industry. With extensive experience in research and development, he has played a pivotal role in advancing sustainable solutions within the field. Today, Ivan shares insights into Cemvita’s groundbreaking advancements and their impact on the bioeconomy.

Can you explain what Cemvita’s recent breakthroughs in biotechnology and biomanufacturing are?

Cemvita has recently achieved two major breakthroughs that demonstrate its leadership in creating a circular bioeconomy. First, we’ve significantly increased the productivity of our FermOil™ microorganism, reaching this milestone six months earlier than anticipated. This achievement was facilitated by utilizing crude glycerol from biodiesel industries. Moreover, our soil bio-stimulant, FermNPK™, has exhibited remarkable properties for soil health and regeneration, providing essential nutrients that support biodiversity in the soil.

How did Cemvita manage to increase the productivity of the FermOil™ microorganism six months ahead of schedule?

The accelerated productivity of FermOil™ was a result of meticulous research and innovation. By incorporating crude glycerol from biodiesel industries as a feedstock, we enhanced the efficiency of our microorganism. This approach not only improved the productivity but also made the process more economically viable, demonstrating the potential of waste-derived inputs in biomanufacturing.

What role does crude glycerol from biodiesel industries play in enhancing FermOil™ productivity?

Crude glycerol acts as an effective substrate for our microorganism, offering a sustainable and cost-efficient alternative. Its utilization reflects our commitment to transforming industrial waste into valuable resources, which in turn boosts the overall productivity of FermOil™. This approach aligns with our goal of developing eco-friendly solutions that minimize reliance on conventional resources.

How does the improvement in FermWorks™ contribute to Cemvita’s goals of scalability and cost-effectiveness?

The advancements in FermWorks™ make our biomanufacturing plant more scalable and cost-effective. By increasing the productivity of our processes and reducing operational costs, we can produce our bio-based products on a larger scale without compromising on efficiency. This scalability is crucial for fulfilling market demands and advancing our sustainability agenda.

Can you elaborate on the properties of FermNPK™ and why they are considered outstanding for soil health?

FermNPK™ is distinguished by its ability to provide essential nutrients such as nitrogen, phosphorus, and potassium, along with micronutrients and organic compounds like carbohydrates and proteins. These elements are vital for fostering soil microbial life and enhancing biodiversity, making FermNPK™ an excellent tool for regenerative agriculture and soil restoration.

What nutrients and organic compounds does FermNPK™ provide that are beneficial for soil health and biodiversity?

FermNPK™ supplies a rich blend of fundamental nutrients: nitrogen, phosphorus, and potassium, accompanied by crucial micronutrients. Additionally, it provides organic compounds such as carbohydrates and proteins, which bolster soil microbial ecosystems, promoting biodiversity and a healthier soil environment conducive to sustainable agriculture.

How does FermNPK™ contribute to regenerative agriculture and the reduction of synthetic fertilizers?

FermNPK™ plays a central role in regenerative agriculture by restoring degraded soils, particularly in desertic regions. Its nutrient-rich formula reduces the need for synthetic fertilizers, thereby supporting soil health and encouraging sustainable farming practices that are beneficial for the environment.

In what ways does Cemvita prioritize sustainability beyond just carbon reduction?

At Cemvita, sustainability is holistic. We adhere to planetary boundaries, ensuring that our product development minimizes land use, water footprint, and biodiversity loss. We design our products with the planet’s health in mind, considering not just carbon reduction but overall ecological balance.

How does applying planetary boundaries influence Cemvita’s product development process?

Implementing planetary boundaries in our product development ensures that we remain focused on creating solutions that are ecologically sound. This approach helps us in reducing land and water usage, and curbing biodiversity loss, ultimately fostering products that align with the planet’s long-term health.

What are the environmental benefits of using FermOil™ as a low-carbon alternative for sustainable aviation fuel?

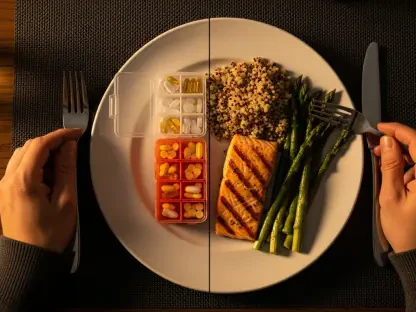

FermOil™ offers significant environmental benefits as a sustainable aviation fuel. Its production involves converting industrial waste into fuel, thereby eliminating the need for land and freshwater resources. This provides a low-carbon alternative that decreases aviation’s environmental impact.

How does the use of industrial waste like glycerol help in reducing land and freshwater usage?

Using industrial waste, such as glycerol, enables us to produce bio-based products without the extensive land and freshwater requirements typically associated with agriculture. By recycling waste, we’re contributing to a more sustainable manufacturing process that conserves vital natural resources.

What sustainability incentives is Cemvita targeting with its waste-to-value platform?

Cemvita’s waste-to-value platform opens up avenues for various sustainability incentives, including tax credits, carbon markets, and government subsidies. By converting waste into valuable products, we’re positioned to benefit from incentives that encourage sustainable practices.

How has the leadership of the Chief Science and Sustainability Officer contributed to Cemvita’s sustainability goals?

Our Chief Science and Sustainability Officer has been instrumental in guiding Cemvita’s sustainability agenda. Her leadership emphasizes a comprehensive approach to designing products that benefit entire ecosystems, and her visionary strategies ensure that our sustainability goals are met.

Can you provide examples of how Cemvita designs its products with the planet in mind?

Cemvita designs its products by considering the full environmental impact, from the microorganisms we engineer to the ecosystems we aim to heal. This holistic approach ensures that our products support planetary health and are in harmony with sustainable practices.

How do the advancements in FermOil™ and FermNPK™ help in derisking the FermWorks™ project?

These advancements reduce risks associated with scalability and environmental compliance. By improving productivity and showcasing the efficacy of our products, we enhance the reliability of our FermWorks™ project, thereby strengthening our position in the biomanufacturing industry.

Why is the new model of industrial-scale, waste-to-value biomanufacturing considered viable based on Cemvita’s progress?

Cemvita’s progress demonstrates the viability of an industrial-scale, waste-to-value biomanufacturing model by successfully converting waste into sustainable products. Our capability to scale these operations while maintaining eco-efficiency highlights the potential for widespread adoption of this innovative approach.