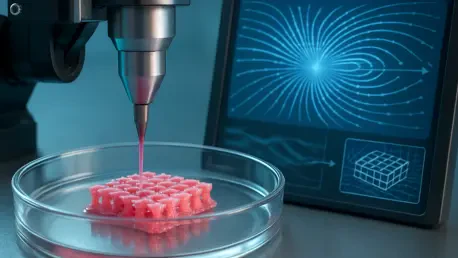

Imagine a world where the replacement of damaged organs or tissues isn’t a distant dream but a tangible reality, crafted with precision to match an individual’s unique biology. This vision is becoming increasingly achievable through the remarkable advancements in 3D bioprinting, a technology that stands at the cutting edge of regenerative medicine. Among the most exciting developments in this field is vector field-guided toolpathing, a pioneering method introduced by Griffin et al. in their recent publication in Communications Engineering. This innovative approach leverages sophisticated computational models to direct the printing process in three dimensions, achieving unparalleled accuracy in replicating the complex structures of natural tissues. By moving beyond the limitations of traditional bioprinting techniques, this technology offers a transformative solution to long-standing challenges in tissue engineering. It sets the stage for creating functional, lifelike constructs that could redefine medical treatments and extend into other groundbreaking applications.

Overcoming the Limits of Conventional Methods

The journey of 3D bioprinting has been marked by significant hurdles, particularly with conventional techniques that rely on a simplistic layer-by-layer deposition of bioink. These older methods often produce structures with inconsistent mechanical properties, lacking the intricate fiber alignment necessary for mimicking real tissues. As a result, the bioprinted constructs frequently fail to integrate effectively with the human body, limiting their practical use in medical applications. Vector field-guided toolpathing emerges as a revolutionary answer to these issues by introducing a dynamic way to control the print head’s movement. Through the use of mathematically derived vector fields, this approach ensures that bioink is deposited along precise paths tailored to the specific architecture of the target tissue. Such precision enhances structural integrity, making the resulting constructs far more viable for therapeutic purposes and setting a new standard for what bioprinting can achieve in terms of functionality and realism.

Another critical advantage of this method lies in its reliance on advanced computational simulations to map out the ideal printing path before the process even begins. These simulations analyze the biomechanical and geometric requirements of the tissue, creating a detailed 3D vector field that guides the printer with exacting accuracy. Unlike the rigid, predictable patterns of traditional bioprinting, this technology adapts to the unique needs of each construct, ensuring that every layer contributes to a cohesive and biologically relevant whole. The improvement in control over fiber orientation and density directly addresses past shortcomings, such as poor cell alignment and inadequate strength. By doing so, it opens the door to creating tissues that not only look like their natural counterparts but also perform similarly under physiological conditions, marking a significant leap forward for the field of regenerative medicine and its potential to heal complex injuries or replace failing organs.

Replicating the Intricacies of Natural Design

One of the most compelling aspects of vector field-guided toolpathing is its ability to emulate the sophisticated organization found in the body’s own tissues, a feat that has long eluded bioprinting technologies. Natural structures like muscles, ligaments, and neural pathways depend on highly specific fiber arrangements within the extracellular matrix for their strength and functionality. This method excels by aligning bioink filaments in patterns that closely mirror these native configurations, creating an environment where cells can thrive. Early laboratory experiments have demonstrated promising results, with cells showing enhanced alignment and growth along the guided paths. Such outcomes suggest that bioprinted tissues produced through this technique could integrate more seamlessly into the human body, offering hope for more effective treatments in areas ranging from injury repair to chronic disease management.

Beyond mere structural accuracy, the biomimetic approach of this technology fosters a deeper level of biological compatibility that is vital for long-term success in medical applications. By replicating the hierarchical design of natural tissues, vector field-guided toolpathing supports critical cellular processes such as proliferation and differentiation, which are essential for tissue maturation. This means that the resulting constructs are not just passive scaffolds but active environments that encourage cells to behave as they would in a living organism. The implications are profound, particularly for creating implants that must withstand the dynamic stresses of the body while promoting healing. As research progresses, this ability to mirror nature’s blueprint could lead to breakthroughs in producing complex tissues like heart muscle or vascular networks, areas where precise structural alignment is non-negotiable for achieving functional outcomes in clinical settings.

Expanding Horizons Across Industries

The transformative potential of vector field-guided toolpathing is not confined to the realm of healthcare; its impact reaches into diverse fields where controlled material properties are paramount. In soft robotics, for instance, the ability to program specific fiber directions and densities enables the creation of flexible, muscle-like components that can mimic biological movement. This opens up exciting possibilities for developing advanced robotic systems that interact more naturally with their environments. Additionally, the technology shows promise in the design of biohybrid devices, which combine living and synthetic elements to create innovative solutions for both medical and industrial challenges. The versatility of this approach underscores its value as a cross-disciplinary tool, capable of driving innovation far beyond its initial scope in tissue engineering.

Scalability further enhances the appeal of this method, as it can be applied to a wide range of projects, from crafting microscale capillary channels to building large organ-like scaffolds for transplantation. This adaptability makes it particularly suited for personalized medicine, where patient-specific grafts can be designed to match an individual’s unique anatomical needs. Such tailored solutions could significantly improve treatment outcomes by reducing the risk of complications like rejection or poor integration. The broad applicability of vector field-guided toolpathing signals a shift in how additive manufacturing is perceived, positioning it as a foundational technology that could influence everything from clinical therapies to cutting-edge engineering. As adoption grows, the method’s ability to bridge multiple domains will likely inspire new collaborations and applications, reshaping industries in unexpected and impactful ways.

Driving Precision and Tailored Solutions

At the core of vector field-guided toolpathing is an unwavering commitment to precision, achieved through the seamless integration of computational modeling, robotics, and real-time monitoring systems. Advanced algorithms calculate the optimal path for the print head, while sensors provide continuous feedback to adjust speed, direction, and extrusion rates during the printing process. This dynamic control ensures that every droplet of bioink is placed with pinpoint accuracy, even when faced with variables such as fluctuating material viscosity. The result is a level of consistency and fidelity that traditional bioprinting struggles to match, making it possible to produce constructs with the exact structural and mechanical properties needed for their intended function. This meticulous approach is a game-changer for creating reliable, high-quality tissues that can withstand the rigors of implantation and long-term use in the body.

Looking ahead, the potential for personalization elevates this technology to new heights, particularly with the prospect of integrating artificial intelligence into the workflow. By analyzing patient-specific imaging data, AI could predict and generate vector fields customized to an individual’s anatomy, paving the way for truly bespoke bioprinted solutions. Such advancements could revolutionize treatments by ensuring that implants are not only structurally accurate but also biologically optimized to minimize immune responses. This focus on tailored outcomes aligns with broader trends in healthcare, where the emphasis is increasingly on individualized care. As the technology matures over the coming years, from now through 2027 and beyond, it could play a central role in addressing critical challenges like organ shortages, offering faster, safer alternatives to conventional transplantation methods and transforming the landscape of medical intervention.

Charting the Path Forward in Biofabrication

Reflecting on the strides made by vector field-guided toolpathing, it’s evident that this method marks a pivotal moment in the evolution of 3D bioprinting. Its ability to transcend the constraints of earlier techniques through precise, biomimetic deposition has reshaped expectations for what engineered tissues can achieve. The integration of computational guidance with mechanical accuracy delivers constructs that are not only structurally sound but also biologically relevant, as validated by early in vitro studies. While obstacles like achieving full vascularization in thicker tissues persist, the groundwork laid by this innovation offers a clear direction for overcoming such hurdles through complementary approaches like coaxial printing.

Moving into the future, the focus should shift toward accelerating the clinical translation of this technology by refining bioink formulations and enhancing integration with AI-driven personalization tools. Collaborative efforts across disciplines will be crucial to tackle remaining challenges, ensuring that the benefits of tailored implants reach patients in need. Exploring partnerships with material scientists and robotic engineers could further optimize the process, while investment in open-source platforms might democratize access to these tools. Ultimately, the legacy of this advancement lies in its potential to redefine healthcare, providing actionable pathways to alleviate organ scarcity and improve therapeutic outcomes on a global scale.