The Advanced Biofuels and Bioproducts Process Development Unit (ABPDU) stands as a formidable force reshaping the U.S. biomanufacturing sector amid the demand for sustainable and efficient biotechnological solutions. Since its inception in 2009 under the U.S. Department of Energy’s Bioenergy Technologies Office and managed by the Lawrence Berkeley National Laboratory, this transformative facility has actively engaged with over 90 companies, predominantly U.S.-based, to assist them in scaling up and commercializing their innovative biotechnologies. By providing a fusion of state-of-the-art infrastructure and meaningful collaborations, ABPDU has become a vital player in driving the biomanufacturing industry towards a more sustainable future. This article delves into how ABPDU’s extensive resources empower startups, its partnerships aimed at sustainable innovation, and success stories showcasing its pivotal role in advancing biotechnology within the United States.

Empowering Startups with Resources and Expertise

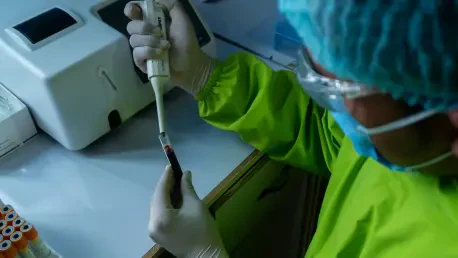

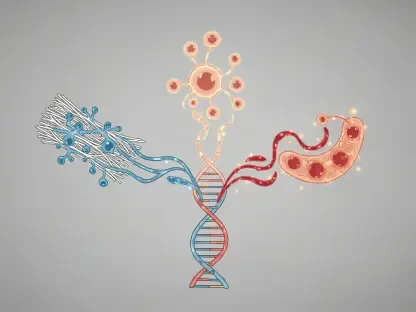

ABPDU offers a unique blend of infrastructure and expertise crucial for startups seeking a foothold in the challenging world of biomanufacturing. The unit’s state-of-the-art facilities, which include advanced equipment like deconstruction, fermentation, and downstream recovery technology, play a critical role in helping new ventures move beyond theoretical concepts into practical implementation. This comprehensive support empowers startups to pilot and refine their biotechnological products, minimizing risks and bolstering scalability. Furthermore, the facility’s engineering and analytical services provide tailored solutions that address specific challenges faced by businesses in this dynamic industry, fostering a conducive environment for innovation and growth.

In a sector where economic viability and scalability are pivotal, ABPDU’s resources are indispensable. They enable startups to pursue ambitious projects without the prohibitive capital expenditure typically associated with high-tech equipment and specialized expertise. The approach effectively reduces barriers to entry for emerging businesses, allowing them to focus on innovation rather than infrastructure concerns. By accelerating the development of new products and technologies, ABPDU supports the rapid transition from lab-scale experimentation to full-scale manufacturing. This capability not only benefits individual companies but also strengthens the broader biomanufacturing landscape in the United States, paving the way for future advancements and breakthroughs in the field.

Collaborations Focused on Sustainable Innovation

ABPDU’s strategic collaborations with various startups underscore a significant shift within the biomanufacturing sector towards sustainable and bio-based production methodologies. Companies like Checkerspot, Huue, and Oobli exemplify this movement, with their pioneering approaches aimed at replacing traditional materials and processes with eco-friendly alternatives. These partnerships reflect a broader industry trend, driven by growing consumer awareness and regulatory pressures, emphasizing the need for environmentally responsible and sustainable solutions in manufacturing.

Through its collaboration efforts, ABPDU provides vital support to its partners, assisting them in navigating the complex journey from concept to market readiness. For instance, ABPDU contributed significantly to Checkerspot’s success in utilizing algae oils for creating advanced polymers, demonstrating the material’s superior properties over conventional plastics. Such innovation has enabled the development of products like the Intention 110 ski model, showcasing potential applications across various industries. Similarly, Huue’s work with ABPDU in microbial biosynthesis has revolutionized the denim industry by producing a nontoxic indigo dye, setting a new standard by eliminating harmful chemicals traditionally used in dye production. These collaborations not only advance the frontiers of sustainable manufacturing but also highlight ABPDU’s role as an incubator for technological advancements that align with evolving environmental and market needs.

Success Stories in Biotechnological Advancement

The tangible outcomes of ABPDU’s involvement with its partners are vividly illustrated in several success stories that highlight significant advancements in biotechnology. One prominent example is Checkerspot’s collaboration with ABPDU, where the company developed groundbreaking algae-based oils, which were then used to create advanced polymers. These superior materials led to the production of high-performance recreational equipment, such as the Intention 110 ski, demonstrating improved durability and performance over traditional materials. This case exemplifies how ABPDU’s support can facilitate the translation of innovative ideas into market-ready products, offering substantial benefits across diverse industries beyond recreation.

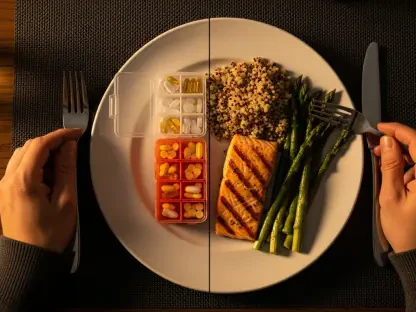

Another notable success is Huue’s pioneering work in microbial biosynthesis for nontoxic indigo dye production. Thanks to ABPDU’s expertise, Huue efficiently scaled their process to produce enough dye for commercial demonstration within a remarkably short time. This breakthrough poses a sustainable alternative to conventional dyeing methods riddled with toxic chemicals, revolutionizing the fashion industry’s approach to environmental responsibility. Similarly, Oobli, formerly Joywell Foods, has leveraged ABPDU’s resources to scale up production of its innovative sweet proteins. These proteins offer the sweetness of sugar without adverse health effects or environmental costs associated with conventional sweeteners. This advancement addresses critical consumer concerns related to diet and health, underscoring the potential of biotechnology to transform industries fundamentally.

Innovating with Almond Shell Waste and Pandemic Responses

Beyond direct collaborations with startups, ABPDU has demonstrated its capability to innovate in solving broader industrial challenges, exemplified by its efforts in repurposing agricultural waste. A significant initiative involves converting almond shell waste—a byproduct of California’s massive almond production—through torrefaction into a biodegradable reinforcing agent for plastics. This novel approach not only offers a cost-effective alternative to traditional waste conversion methods, such as bioethanol production but also provides a sustainable solution that reduces environmental impacts associated with plastics. ABPDU’s ingenious analysis encourages industry stakeholders to reconsider waste as a valuable resource, representing a vital step towards circular economy principles.

Additionally, during pandemic challenges, ABPDU extended its support to enhance response capabilities for San Francisco-based companies Caspr Biotech and Swiftscale Biologics. By aiding these companies in scaling up their technology, ABPDU bolstered crucial advancements in pandemic response initiatives. Caspr Biotech successfully developed a COVID-19 testing kit leveraging CRISPR technology, while Swiftscale Biologics expanded its production capacity for neutralizing antibodies, essential for pathogen detection and immune responses. This assistance highlights ABPDU’s flexibility and readiness to respond to urgent societal needs, reinforcing its role as a key player in addressing both immediate and long-term biomanufacturing challenges.

Berkeley Lab’s Tradition of Collaborative Innovation

The symbiotic relationship between ABPDU and Berkeley Lab encapsulates a long-standing tradition of fostering innovation through collaboration. Lawrence Berkeley National Laboratory has played a pivotal role in supporting ABPDU’s mission, drawing from its extensive expertise in scientific research and problem-solving. This collaboration has yielded significant scientific achievements, underscored by Berkeley Lab’s impressive legacy of Nobel Prizes, which attest to its culture of excellence and dedication to advancing knowledge across diverse fields. Such a collaborative spirit has been a crucial element in enabling ABPDU to drive substantial progress in biotechnological innovation, underlining the importance of institutional support in fostering industry breakthroughs.

Berkeley Lab’s infrastructure and intellectual resources have provided ABPDU with a solid foundation, allowing it to pursue ambitious projects and facilitate transformative advancements in biomanufacturing. This partnership showcases the mutual benefits of combining academic expertise with practical application, creating an environment where cutting-edge research can seamlessly transition into real-world solutions. By continuously pushing the boundaries of what is possible through science and technology, Berkeley Lab and ABPDU embody a commitment to harnessing knowledge for the greater good, thereby contributing to sustained innovation and economic growth.

Transforming the Biomanufacturing Landscape

ABPDU is a vital asset for startups venturing into the demanding realm of biomanufacturing. Its cutting-edge infrastructure, which includes sophisticated tools for deconstruction, fermentation, and downstream recovery, is essential for translating theoretical concepts into practical applications. By providing this comprehensive support, ABPDU allows startups to pilot and refine their biotechnological innovations, reducing risks and enhancing scalability. Moreover, the unit offers engineering and analytical services that address specific hurdles businesses face in this dynamic sector, thereby fostering innovation and growth.

In an industry where economic practicality and scalability are crucial, ABPDU’s resources are invaluable. They empower startups to pursue ambitious initiatives without the hefty investment typically needed for high-tech equipment and expertise. This approach lowers entry barriers for new businesses, shifting their focus from infrastructure woes to innovation. By hastening the progression from lab experiments to full-scale production, ABPDU bolsters not just individual companies but also the overall U.S. biomanufacturing landscape, paving the way for future breakthroughs.