In the fast-evolving landscape of biopharmaceutical production, ensuring the consistency of cell culture media stands as a cornerstone for achieving reliable cell growth and high-quality therapeutic products, especially given the complexity of these media formulations. With hundreds of components like amino acids, vitamins, and growth factors, even the smallest variations can significantly alter outcomes, potentially compromising product yield and safety. Traditional methods for monitoring media composition, while detailed, often fall short due to their time-intensive nature and high costs, leaving a gap for innovative solutions. Enter fluorescence spectroscopy with A-TEEM (Absorbance, Transmittance, and Excitation-Emission Matrices), a cutting-edge technology that promises to transform quality control in biomanufacturing. This approach offers rapid, cost-effective, and precise molecular profiling, enabling the detection of subtle compositional changes that could impact cell performance. By addressing the limitations of conventional techniques, this tool is poised to redefine how variability is managed in both research and industrial settings, paving the way for enhanced process reliability.

1. Unveiling the Challenges of Cell Culture Media Consistency

Maintaining uniformity in cell culture media is paramount for biotherapeutic production, as these complex mixtures provide the essential nutrients and growth factors necessary for cell proliferation and product synthesis. However, the certificates of analysis provided with commercial media often cover only basic parameters such as pH and osmolality, offering limited insight into the full spectrum of compositional variability. This gap necessitates additional qualification systems by end users to evaluate potential impacts on yield and quality. The intricate nature of media, with components ranging from sugars to trace elements, poses significant analytical challenges. Conventional methods struggle to capture the heterogeneity of these formulations, often missing subtle differences that could affect cell behavior. This underscores the urgent need for advanced tools capable of delivering comprehensive and actionable data to ensure consistent performance across batches.

Traditional analytical techniques like high-performance liquid chromatography (HPLC) and liquid chromatography-mass spectrometry (LC-MS) provide detailed compositional breakdowns but come with significant drawbacks. These methods require extensive sample preparation, specialized equipment, and lengthy processing times, rendering them impractical for high-throughput screening in biomanufacturing environments. Furthermore, routine quality control metrics such as pH and osmolality fail to offer the granular insights needed to detect specific molecular variations. As a result, the biopharmaceutical industry has long sought alternatives that can balance precision with efficiency. The limitations of these established approaches highlight the critical demand for innovative technologies that can streamline media monitoring while maintaining a high level of accuracy, ultimately supporting robust process control in production settings.

2. Introducing A-TEEM as a Game-Changing Solution

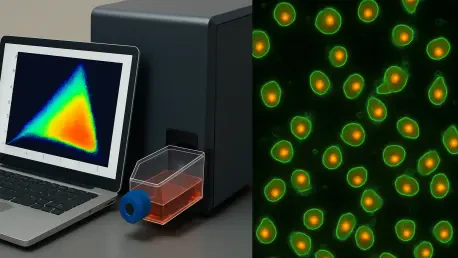

Fluorescence spectroscopy, particularly through the application of A-TEEM, emerges as a promising solution to the challenges of monitoring cell culture media variability. This technique stands out for its rapid, non-invasive, and cost-effective approach, delivering a unique molecular fingerprint of media compositions. By simultaneously capturing absorbance, transmittance, and excitation-emission matrices, A-TEEM enables comprehensive optical characterization, identifying a wide range of fluorophores and chromophores present in the media. When paired with multivariate analysis tools like parallel factor analysis (PARAFAC) and principal component analysis (PCA), it becomes possible to classify media types, track compositional shifts over time, and monitor storage condition impacts. This powerful combination offers a level of detail and speed that traditional methods cannot match, positioning A-TEEM as a transformative tool for quality assurance.

The origins of fluorescence excitation-emission spectroscopy for media characterization trace back to pioneering research by Alan G. Ryder’s group at the University of Galway in Ireland. Their work demonstrated the potential of fluorescence-based methods to provide real-time, non-invasive molecular insights, effectively overcoming the constraints of conventional analytical approaches. Unlike HPLC or LC-MS, which demand hours for results, A-TEEM assessments can be completed in minutes, requiring minimal sample preparation and equipment investment. This efficiency, coupled with the ability to detect even minor compositional changes, makes the technology particularly suited for biopharmaceutical manufacturing, where time and consistency are critical. As a result, A-TEEM not only addresses existing gaps but also sets a new standard for media evaluation in both research and industrial applications.

3. Methodology Behind A-TEEM’s Application

To rigorously evaluate the capability of A-TEEM in tracking lot-to-lot variability, a detailed methodology was employed using commercially sourced GMP-ready yeastolate batches. Twelve distinct lots were obtained, with samples prepared at a concentration of approximately 0.3 mg/mL by dissolving 9–10 mg of media in 30 mL of pH 7.4 phosphate-buffered saline. Triplicates of each lot were prepared over two days, resulting in six samples per lot for comprehensive analysis. Data collection utilized a spectrofluorometer to acquire A-TEEM profiles, capturing absorbance, transmittance, and excitation-emission matrices across a wavelength range of 250–800 nm with a 5 nm step size. Two acquisition methods were applied: one for the amino acid region with a 0.1-second integration time and another for the vitamin region with a 1-second integration time, ensuring precise measurements across different molecular components.

Corrections for spectral accuracy, inner-filter effects, Rayleigh scatter masking, and Raman scatter normalization were meticulously applied during data acquisition, with a blank reference recorded for calibration. The collected optical data underwent multivariate analysis using PARAFAC, a multi-dimensional decomposition method that extends beyond principal component analysis to handle higher-order datasets. By combining amino acid and vitamin region datasets, PARAFAC extracted key spectral features to quantify variability across lots, supported by specialized software for modeling. This structured approach allowed for the effective classification of media batches, providing a robust framework to monitor compositional differences. The methodology underscores A-TEEM’s potential as a reliable, efficient tool for ensuring media quality before use in bioreactors, addressing critical needs in bioprocess control.

4. Insights from A-TEEM Data and Variability Analysis

The application of A-TEEM combined with PARAFAC or PCA has revealed intricate molecular distinctions in cell culture media, enabling successful classification and component quantification. Spectral features associated with fluorophores such as tryptophan, tyrosine, pyridoxine, folic acid, and riboflavin drive the separation of media types, offering insights far beyond traditional chemical analysis. These molecular signatures provide a holistic view of media composition, identifying variations that could influence cell growth and product outcomes. In a specific study involving 12 lots of GMP-ready yeastolate media, with six preparations per lot, A-TEEM fingerprints highlighted clear differences. For instance, one lot exhibited higher tyrosine content relative to tryptophan, while another showed elevated riboflavin compared to pyridoxine, demonstrating the technology’s sensitivity to subtle shifts.

Further analysis through a calibrated five-component PARAFAC model captured 99.9% of the variance, decomposing fluorescence signals into major fluorophores and distinguishing lots via 3D cluster plots. A quantitative approach using PARAFAC scores, calibrated with pure standards, allowed for the calculation of component concentrations across batches. Variability remained consistent, with tryptophan and tyrosine levels aligning closely with catalog values, though considerations for protein-bound forms in media were noted. These findings emphasize A-TEEM’s ability to not only detect but also quantify lot-to-lot differences, providing actionable data for quality control. The precision and depth of this analysis mark a significant advancement over conventional methods, offering biopharmaceutical producers a powerful means to ensure media consistency and mitigate risks in cell culture performance.

5. Implications for Biopharmaceutical Production Excellence

The demonstrated effectiveness of A-TEEM and multivariate analysis in monitoring cell culture media variability carries profound implications for the biotherapeutic industry. By serving as a quality control tool, this technology ensures media consistency before use in bioreactors, potentially reducing unexpected performance issues and enhancing process robustness. Unlike traditional methods that require hours for analysis, A-TEEM delivers results in minutes, minimizing downtime in production workflows. Its cost-effectiveness, driven by minimal sample preparation and equipment needs, further positions it as an attractive alternative for manufacturers seeking to optimize resources without sacrificing accuracy. The ability to gain molecular-level insights into media composition equips producers with a deeper understanding of factors influencing cell behavior, fostering more predictable outcomes.

Beyond immediate quality assurance, A-TEEM offers predictive capabilities by enabling early detection of potential media degradation, a critical advantage in maintaining long-term process stability. This rapid, comprehensive approach supports proactive decision-making, allowing adjustments before issues escalate into costly production setbacks. The transformative potential of fluorescence spectroscopy combined with multivariate analysis lies in its adaptability to diverse biomanufacturing contexts, from small-scale research to large-scale commercial production. As the industry continues to prioritize efficiency and reliability, integrating such innovative tools can redefine standards for media management. Ultimately, A-TEEM paves the way for improved control over bioprocesses, ensuring that the foundation of therapeutic production remains solid and consistent.

6. Reflecting on a Path Forward with Advanced Media Monitoring

Looking back, the exploration of A-TEEM paired with multivariate analysis proved to be a pivotal step in addressing the longstanding challenge of cell culture media variability. This approach successfully tracked lot-to-lot differences with unparalleled speed and precision, offering a reliable method to safeguard media quality prior to bioreactor application. The integration of absorbance, transmittance, and excitation-emission data through PARAFAC analysis provided a clear window into molecular compositions, ensuring that even minor deviations were identified and addressed. Such advancements marked a significant departure from the slow, resource-heavy traditional methods, setting a new benchmark for efficiency in biopharmaceutical quality control.

Moving forward, adopting A-TEEM as a standard tool in biomanufacturing holds immense potential for elevating process reliability and product consistency. Industry stakeholders are encouraged to explore pilot implementations of this technology, tailoring its application to specific media formulations and production scales. Collaborative efforts between researchers and manufacturers could further refine multivariate models, enhancing predictive accuracy for diverse bioprocess scenarios. Additionally, integrating A-TEEM data with digital monitoring systems may offer real-time insights, streamlining decision-making in dynamic production environments. By embracing these next steps, the biotherapeutic sector can build on past successes, ensuring that innovations in media monitoring continue to drive progress and uphold the highest standards of therapeutic development.