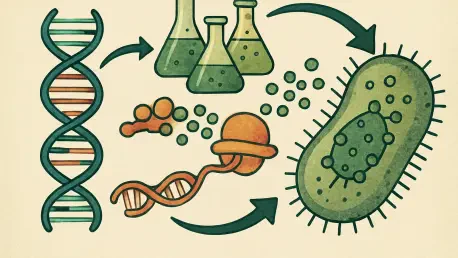

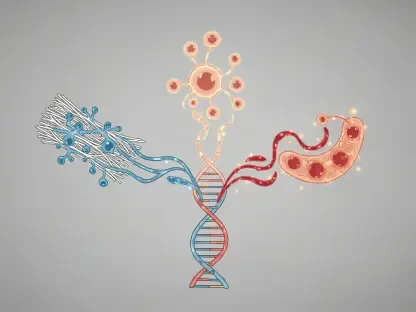

In the rapidly evolving field of synthetic biology, a groundbreaking study from the University of Warwick has unveiled a transformative approach to enhance the productivity of engineered microbial cell factories, as detailed in a recent publication in Nature Communications. These microscopic biofactories, often bacteria modified with synthetic genetic circuits, hold immense promise for producing critical chemicals used in medicine, industrial processes, and environmental solutions. However, their potential has been consistently undermined by evolutionary instability, where the burden of production leads to diminished output over time. This research introduces an innovative genetic feedback system designed to address these challenges, offering a potential game-changer for the scalability and sustainability of biofactories. By integrating principles from control engineering, the study paves the way for longer-lasting and more efficient microbial systems, sparking excitement about the future of biomanufacturing across diverse sectors.

Tackling the Evolutionary Roadblock

The primary hurdle in utilizing engineered bacteria for chemical production lies in the metabolic stress imposed by their modified genetic circuits. When tasked with synthesizing valuable compounds, these cells experience slowed growth rates, creating an environment where non-producing mutants—cells that disable their synthetic circuits to focus on reproduction—gain a competitive edge. Over successive generations, the population of functional cells dwindles, drastically reducing the biofactory’s lifespan and overall yield. This evolutionary conflict has long frustrated scientists aiming to harness microbes for large-scale applications, as the balance between cellular health and productivity remains elusive. The University of Warwick’s research directly confronts this issue, seeking to redefine how engineered cells can maintain their function under such pressures.

Beyond identifying the problem, the study delves into the mechanics of why mutants dominate so quickly in these systems. The metabolic burden not only hampers growth but also triggers a feedback loop where any cell that escapes production duties multiplies faster, overtaking the population. This dynamic poses a significant barrier to industrial use, where consistency and longevity are paramount. By framing this as an evolutionary battle within microbial communities, the research highlights the urgent need for innovative strategies that prioritize sustained performance over short-term gains. This perspective sets the stage for a solution that could transform the practical utility of biofactories.

Merging Biology with Control Theory

To address the instability of engineered cells, the Warwick team adopted an interdisciplinary approach, blending synthetic biology with principles from control engineering. A comprehensive computational model was developed to simulate bacterial behavior, capturing critical factors such as growth rates, mutation frequencies, and competitive dynamics in a virtual lab setting. This digital platform enabled the researchers to experiment with numerous genetic circuit designs without the time and cost of physical testing, pinpointing configurations that optimize both cell longevity and chemical output. Such a fusion of disciplines illustrates the power of applying engineering frameworks to biological challenges, offering a blueprint for future innovations in biotechnology.

This computational approach also provided insights into how different variables interact within a microbial population over time. By simulating countless scenarios, the model revealed patterns of instability that might not be evident in early lab experiments, allowing for preemptive adjustments to genetic designs. The ability to predict outcomes before implementation marks a significant advancement, reducing trial-and-error cycles and focusing resources on the most promising solutions. This methodical integration of technology and biology underscores a shift toward smarter, data-driven strategies in synthetic biology, potentially accelerating the development of robust biofactories for real-world applications.

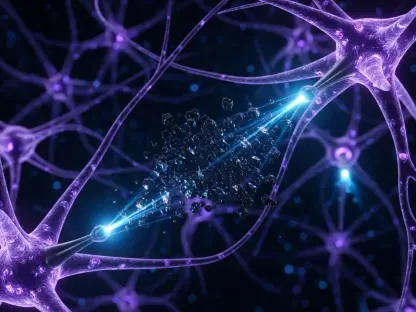

Introducing the Genetic Thermostat Concept

Central to the Warwick study is the development of a dual-feedback control system, often described as a “genetic thermostat” for its ability to regulate cellular processes dynamically. This system continuously monitors internal conditions within the bacteria, such as the rate of chemical production and the overall health of growth cycles. When production stress threatens cell viability, the mechanism reduces output to alleviate pressure; conversely, it increases activity when conditions support higher yields. This adaptive response prevents the rise of non-producing mutants by maintaining a delicate balance, significantly extending the operational lifespan of engineered cells compared to static systems.

The brilliance of this genetic thermostat lies in its ability to respond in real time to the evolving needs of the microbial population. Unlike rigid genetic circuits that operate at a fixed capacity regardless of cellular strain, this feedback loop acts as a safeguard, ensuring that production does not come at the cost of survival. Simulations suggest that this dynamic adjustment can triple the evolutionary longevity of biofactories, a leap forward from traditional designs that often falter within a short timeframe. By prioritizing sustainability, this innovation addresses a critical gap in synthetic biology, offering a glimpse into how engineered microbes might one day operate reliably over industrial timescales.

Outperforming Traditional Stabilization Techniques

Historically, efforts to stabilize engineered cells have relied on methods like antibiotics to suppress mutant populations or complex genetic modifications requiring multiple stages of engineering. These approaches, while sometimes effective, introduce significant drawbacks, including high costs, increased operational complexity, and risks such as the development of antibiotic resistance. In contrast, the genetic feedback system proposed by the Warwick team offers a streamlined alternative that avoids these pitfalls. By embedding self-regulation directly into the cells, it reduces the need for external interventions, making the process more efficient and safer for large-scale use.

Moreover, the simplicity of this feedback mechanism enhances its appeal for industrial adoption. Without the reliance on costly additives or intricate redesigns, the system lowers the barrier to entry for companies looking to integrate biofactories into their production lines. This cost-effectiveness, combined with the reduced environmental footprint from avoiding antibiotics, positions the approach as a forward-thinking solution. As industries increasingly seek sustainable practices, the ability to maintain productivity without compromising safety or expense becomes a compelling advantage, potentially reshaping biomanufacturing standards.

Adapting to a Range of Industrial Needs

One of the standout features of the genetic feedback system is its remarkable versatility across different bacterial hosts and production pathways. With minimal redesign, the controllers can be adapted to suit a variety of applications, from pharmaceutical synthesis to biofuel generation and even environmental remediation efforts. This adaptability ensures that the technology is not confined to a niche but can address diverse challenges within multiple sectors. The potential to customize these systems without extensive overhauls makes them an attractive option for industries aiming to innovate rapidly.

Additionally, the compatibility of these genetic controllers with existing synthetic biology toolkits amplifies their value. They can be integrated with other strategies to further enhance biofactory resilience, creating opportunities for synergistic advancements. Whether applied to producing life-saving drugs or cleaning up pollutants, the flexibility of this system suggests a broad impact, capable of meeting the unique demands of each field. This wide-ranging applicability signals a step toward a more interconnected and adaptable biotech landscape, where solutions can be tailored efficiently to specific goals.

Envisioning a Sustainable Future for Biomanufacturing

The broader implications of this research point to a transformative shift in how biomanufacturing could operate. Computational simulations from the study indicate that the feedback system may triple the lifespan of engineered cells while substantially increasing cumulative chemical output, even if instantaneous per-cell production is slightly lower. This strategic trade-off emphasizes long-term performance, a critical factor for industrial scalability. Should these findings hold in physical experiments, the cost of production could drop significantly, alongside a reduced environmental impact from more efficient processes.

Sustainability in biomanufacturing is not just about output but also about minimizing waste and resource use over time. The ability to maintain a stable population of productive cells for extended periods could revolutionize how industries approach bio-based solutions, from reducing reliance on chemical synthesis to enabling greener alternatives for everyday products. This vision of a sustainable future hinges on innovations like the genetic thermostat, which prioritize endurance without sacrificing efficacy. As global demands for eco-friendly practices grow, such advancements could play a pivotal role in aligning biotechnology with environmental goals.

From Simulation to Real-World Impact

Although the results of the Warwick study are promising, it’s important to note that they are currently based on computational simulations and await confirmation through laboratory testing. This acknowledgment of the gap between theoretical models and practical application reflects a balanced perspective, tempering optimism with the recognition of further steps needed. The path forward involves rigorous experimentation to validate the system’s effectiveness under real conditions, a process that will likely refine the approach further.

Nevertheless, the groundwork laid by this research offers a compelling framework for the future of synthetic biology. By combining insights from biology, engineering, and computational science, it establishes a precedent for designing smarter genetic circuits that can adapt to evolutionary pressures. This interdisciplinary methodology not only addresses current limitations but also inspires confidence in the potential of engineered microbes to become self-regulating platforms. As validation efforts progress, the biotech community watches closely, anticipating a breakthrough that could redefine industrial biomanufacturing for years to come.