The biopharmaceutical industry has seen significant advancements, particularly in the production of monoclonal antibodies (mAbs), which offer personalized therapies for a range of chronic and debilitating conditions. Despite these advancements, manufacturers face growing pressure to expedite the market launch of new therapies safely and efficiently. To address these challenges, Avantor Inc. and the National Institute for Bioprocessing Research and Training (NIBRT) have expanded their partnership to optimize downstream processes in biopharmaceutical manufacturing. This collaboration aims to enhance efficiency, scalability, and productivity through innovative equipment and specialized training.

Advanced Equipment for Real-World Applications

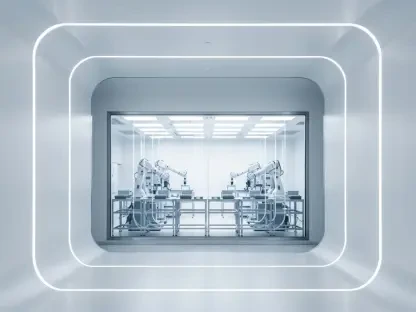

Comprehensive Range of Aseptic Fluid Handling Equipment

Avantor will supply NIBRT with advanced aseptic fluid handling equipment, including Masterflex pump systems and single-use systems. These state-of-the-art tools are designed to replicate real-world biopharmaceutical workflows, providing trainees with practical experience using industry-relevant equipment. By equipping trainees with such technology, Avantor aims to bridge the gap between training and real-world applications in biopharmaceutical manufacturing. The provision of cutting-edge equipment ensures that trainees are adequately prepared to tackle the unique challenges that arise in production environments, ultimately leading to better outcomes for patients and faster time-to-market for new therapies.

Monoclonal antibodies have revolutionized the medical field by providing targeted treatments that alleviate symptoms and slow the progression of chronic diseases. However, manufacturing these complex proteins poses numerous logistical challenges. The equipment supplied by Avantor, such as the Masterflex pump systems, is designed to maintain the integrity of mAbs throughout the production process. These tools support the aseptic transfer of fluids, crucial for maintaining product quality in biomanufacturing. Trainees gain hands-on experience with these systems, allowing them to apply their knowledge practically and effectively, which is critical for minimizing contamination risks and ensuring that therapies are produced to the highest standards.

Importance of Closed Systems and Quality Maintenance

Benoit Gourdier, EVP and Head of Avantor’s Bioscience Production Segment, emphasized the need for optimizing the handling of large-scale fluid volumes while maintaining product quality within a closed system. Such optimization is crucial to avoid delays and product losses, which are common bottlenecks in biopharma manufacturing. Avantor’s advanced equipment aims to ensure seamless and efficient processes, ultimately supporting the biopharma industry in bringing new therapies to market more swiftly. By leveraging their expertise and cutting-edge technologies, Avantor seeks to alleviate production pressures and meet the escalating demand for monoclonal antibodies.

Closed systems are essential in the biopharmaceutical industry due to their ability to minimize contamination risks, thereby ensuring product safety and efficacy. The integration of advanced aseptic fluid handling equipment into training programs at NIBRT allows future industry professionals to become proficient in maintaining these high standards. Benoit Gourdier highlights that handling large fluid volumes efficiently is a cornerstone of successful biomanufacturing. By focusing on both scale and quality, Avantor and NIBRT aim to streamline the production process, reducing the likelihood of costly errors and bottlenecks. This ensures that patients receive lifesaving therapies without unnecessary delays, addressing urgent healthcare needs promptly and effectively.

Targeted Training for Industry Challenges

Expert-Led Training Sessions

In addition to providing cutting-edge equipment, Avantor’s bioprocessing experts are developing targeted training sessions to address scale-up challenges. These expert-led trainings will focus on optimizing downstream processes for mAbs production, utilizing the full capabilities of the Masterflex aseptic fluid transfer systems. The goal is to enhance efficiency and scalability in biopharmaceutical manufacturing, equipping industry partners with the necessary tools and knowledge to maximize productivity. These training sessions are designed to offer practical, hands-on experience with the equipment, allowing trainees to familiarize themselves with different scenarios they might encounter in an actual production setting.

The biopharmaceutical industry’s rapid growth has underscored the need for specialized training that keeps pace with emerging technologies and methodologies. Avantor’s expert-led training sessions are therefore pivotal in cultivating a skilled workforce capable of addressing the complexities of mAbs production. By focusing on downstream processes, these sessions tackle the critical transition from bulk production to the final product, ensuring that every step is fine-tuned for optimal efficiency. The integration of Masterflex systems into these trainings provides a realistic simulation environment where participants can practice and perfect their techniques, thereby enhancing their problem-solving skills and operational knowledge. This comprehensive approach aims to produce competent professionals who can contribute to the industry’s ongoing efforts to bring advanced therapies to market more swiftly and efficiently.

Bridging Knowledge Gaps

Kate Cotter, Director of Training Delivery at NIBRT, expressed the institute’s commitment to providing world-class training and expertise to the biopharma sector. The enhanced partnership with Avantor allows NIBRT to better equip the industry with the tools and knowledge necessary for driving innovation. By combining advanced equipment with specialized training programs, NIBRT aims to empower trainees to meet current and future skills demands confidently. This collaborative effort between Avantor and NIBRT addresses an essential need in the biopharma industry: bridging the gap between theoretical knowledge and practical application in a high-stakes environment.

Knowledge gaps can lead to inefficiencies and errors in the biomanufacturing process, particularly in the complex production of monoclonal antibodies. The specialized training provided by NIBRT and Avantor is designed to empower industry professionals with the knowledge and skills required to excel in their roles. By offering real-world training scenarios utilizing state-of-the-art equipment, the partnership aims to create a workforce that is well-versed in the latest technologies and workflows. This not only enhances individual capabilities but also drives collective progress within the industry, promoting an ecosystem of innovation and efficiency. The confidence and competence gained from such comprehensive training are invaluable in ensuring that new therapies reach patients without unnecessary delays or quality concerns.

Addressing Industry-Wide Challenges

Urgent Challenges in Biopharma Manufacturing

The collaboration between Avantor and NIBRT represents a strategic effort to tackle pressing challenges in biopharmaceutical manufacturing. As research in the field of monoclonal antibodies progresses, there’s a mounting pressure on manufacturers to expedite the safe and efficient market launch of new therapies. By offering state-of-the-art equipment and specialized training, this partnership aims to alleviate these pressures and enhance overall industry productivity. The focus on downstream processing optimization is particularly crucial, as it directly impacts the speed and efficiency of bringing new treatments from the laboratory to the clinic.

As the demand for monoclonal antibodies grows, so does the complexity of their production. The industry faces numerous challenges, including stringent regulatory requirements, maintaining high-quality standards, and navigating the intricacies of large-scale production. Avantor and NIBRT’s partnership aims to address these challenges by equipping the workforce with the necessary expertise and technology. The ability to optimize downstream processes, where many production bottlenecks occur, is vital for meeting market demands and ensuring that life-saving therapies are available to patients who need them. This collaboration highlights the importance of continuous improvement and innovation in biopharmaceutical manufacturing, fostering an environment where cutting-edge treatments can be developed and delivered more efficiently.

Enhancing Productivity and Efficiency

Avantor’s commitment to equipping industry partners with the latest technology and expertise underscores the growing need for efficiency and scalability in biopharmaceutical production. The partnership with NIBRT not only addresses immediate manufacturing challenges but also lays the groundwork for long-term improvements in the industry. As the demand for monoclonal antibodies continues to escalate, such collaborations are vital for driving innovation and improving manufacturing processes. By focusing on both current challenges and future needs, Avantor and NIBRT aim to create a sustainable framework for biopharma manufacturing excellence.

Enhanced productivity and efficiency are not just goals but necessities in today’s competitive biopharmaceutical landscape. Avantor’s advanced equipment and targeted training programs designed in collaboration with NIBRT aim to streamline production processes, minimize waste, and reduce time-to-market for new therapies. This approach addresses both the immediate pressures faced by manufacturers and paves the way for sustained improvements. By fostering a culture of innovation and continuous learning, the partnership supports the industry’s overall growth and ability to meet evolving healthcare needs. The emphasis on both short-term and long-term solutions ensures that the biopharma sector remains resilient and capable of delivering high-quality, life-saving treatments to patients globally.

Broader Context and Industry Developments

Recent Developments in Biopharma

The biopharmaceutical sector has experienced major strides, especially in the development of monoclonal antibodies (mAbs), which provide tailored treatments for various chronic and serious diseases. However, with these advancements, manufacturers are under increasing pressure to bring new therapies to market both quickly and safely. To tackle these challenges, Avantor Inc. has partnered with the National Institute for Bioprocessing Research and Training (NIBRT) to enhance downstream processes in the biopharmaceutical production line. The main goal of this partnership is to improve efficiency, scalability, and overall productivity. This is being pursued through the introduction of cutting-edge equipment and targeted training programs. These steps aim to accelerate the commercialization timeline without compromising safety or effectiveness in the manufacturing of new biopharmaceutical therapies. By optimizing these processes, the industry hopes to meet the growing demand for innovative treatments while maintaining high standards in both production and delivery.