Welcome to the land of biopharmaceuticals, where the wonders of medicine meet with the intricacies of distribution networks. The biopharma sector is blazing a trail in creating life-saving medications, vaccines, and treatments. These aren’t merely commodities, they serve as support for individuals worldwide. Have you ever wondered about the journey these essential medicines undertake, from laboratory experiments to your supply of medications?

Embarking on the journey of a product is a high-stakes venture where accuracy is crucial, and even the slightest error can have an impact. This is the side of biopharma supply chains that guarantees the effective and compliant distribution of biopharmaceuticals to patients who rely on them.

Why should this concern the average person? Well, in biopharma, the supply chain goes beyond handling logistics, it’s also about saving lives. The effectiveness of a life-saving medication can depend on how its supply chain functions, which is a huge responsibility for these distributors. Whether it’s monitoring temperatures or navigating global regulations, every stage in the biopharma supply chain is a reflection of the industry’s dedication to ensuring safety, quality, and accessibility for all.

The Complexity of Biopharma Supply Chains

If we dig a little deeper, it’s clear that the supply chains supporting this industry are anything but ordinary. The products are incredibly sensitive, and the logistics are a global affair.

Global Nature of Biopharma Supply Chains

Imagine a symphony orchestra, but instead of musicians, you have suppliers, manufacturers, and distributors from all corners of the globe playing in harmony. That’s the global biopharma supply chain for you. The active ingredient might be brewed in a bioreactor in Belgium, formulated into a drug in Denmark, packaged in Poland, and then prescribed to a patient in Pennsylvania. Each leg of this journey crosses borders, time zones, and climates, adding layers of complexity to the logistics.

Regulatory Environment

The regulatory environment controls the supply chain, setting the tempo and ensuring everything runs harmoniously. The biopharma industry is one of the most heavily regulated sectors in the world—and with good reason. Every country comes with its own set of rules, regulations, and compliance standards. However, compliance isn’t just about ticking boxes but also about patient safety, product efficacy, and public trust.

Strategies for Compliance

So, how do biopharma companies not just survive but thrive in this amidst all the rules and regulations? It boils down to a few key strategies:

- Know the Rules: Keeping yourself educated on regulatory changes is a full-time job. You need a dedicated team whose sole focus is to monitor, interpret, and implement regulatory updates.

- Build Relationships: Fostering strong relationships with regulatory bodies can do a lot of good for helping you remain compliant, and a constant, open line of communication can help you anticipate changes.

- Invest in Compliance: This means leveraging technology to ensure traceability, quality control, and documentation.

- Plan for Flexibility: Building some room for movement into your supply chain allows you to adapt when regulations shift without warning.

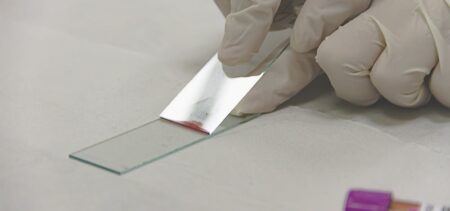

Cold Chain Logistics

Picture this: a world where your medication needs its own personal thermostat, constantly monitored, never allowed to sway too hot or too cold. This is cold chain logistics in a nutshell, where temperature control isn’t just a preference—it’s a necessity.

The Icy Importance of Temperature Control

Biopharmaceutical products are sensitive. Too hot, and these sensitive compounds might degrade, losing their potency. Too cold, and you risk altering their structure, rendering them ineffective or even harmful. This is why temperature control is the heart of cold chain logistics. It’s all about maintaining that ‘just-right’ temperature from the moment a product leaves the manufacturing facility to when it’s safely in the hands of those who need it.

Supply Chain Visibility

Losing track of your shipment of medication could negatively impact the people who need it. This is why it’s so key to keep an eye on everything from start to finish. It changes the game, making everything clear and easy to keep track of.

The Need for Transparency

Making and distributing medication is all about being open and clear every step of the way. It’s crucial to know exactly what’s happening with them from the beginning to the end. Why? Because they’re lifesavers. It’s imperative to track where they are, how they’re handled, and when they’ll arrive. This way, we can make sure the right medicine is delivered where and when it’s needed, and that it’s in good order when it gets there.

Challenges in Achieving End-to-End Visibility

Achieving this level of transparency requires continuous effort and the right tools. Here’s what can cloud the view:

- Complex Networks: The biopharma supply chain isn’t a straight line; it’s a sprawling web of manufacturers, suppliers, distributors, healthcare providers, and more. Each node adds a layer of complexity to tracking and visibility.

- Data Silos: Information tends to get trapped within organizational or technological silos, making it hard to get a unified view of the supply chain. When data doesn’t flow freely, visibility suffers.

- Global and Regulatory Variances: Different countries, different rules. Navigating the diverse regulatory landscapes while maintaining visibility across borders can be a challenge.

Demand Forecasting and Inventory Management

More likely than not, each individual invested in a biopharma supply chain wishes they had a crystal ball to help them see into the future and know how much they’ll need and of what.

Predicting Demand

Predicting demand for biopharmaceutical products is like trying to predict the weather in a notoriously fickle climate. You may have historical data, but there are so many variables at play. New healthcare policies, outbreaks of diseases, advances in medical research, and even social media trends can cause sudden and unpredictable shifts in demand. Plus, with the stakes as high as they are in healthcare, getting these predictions wrong isn’t just a logistical headache; it can directly impact patient care.

The Effects of Inaccurate Forecasts

Forecasts that are inaccurate can send a whole ripple of consequences all throughout the ecosystem. And it can be a slippery slope. Should you overestimate demand, you’re left with excess inventory that’s expensive to store and can even expire if it’s not used.

On the other hand, if you underestimate what you might need, then you’re at risk of stock outs and delayed treatments, as well as a loss of trust with your healthcare providers and patients.

To top it all off, each of the scenarios mentioned above can have an even worse effect on your finances and ethics, because, at the end of the day, it’s a patient’s well-being that hangs in the balance.

Strategies for Effective Inventory Management

So, how do biopharma companies navigate this unpredictable landscape? The key lies in agile and strategic inventory management. This isn’t just about keeping shelves stocked; it’s about creating a responsive and flexible system that can adapt to changes in demand in real time.

One approach is to embrace a more dynamic model of inventory management that uses real-time data and analytics to make adjustments on the fly. This might mean diversifying suppliers to reduce the risk and investing in predictive analytics to better understand demand patterns.

Another strategy is to establish closer collaboration with stakeholders across the supply chain, from suppliers to healthcare providers. Sharing information and insights can lead to a more cohesive approach to managing demand fluctuations. It could also save time, because how much faster would we get to the solutions if we were all brainstorming together and not trying to carry the weight of the burden by ourselves?

Lastly, investing in advanced technologies like AI and machine learning can also give us some more accurate forecasting models. These tools can analyze vast amounts of data and identify patterns, as well as predict changes in demand, much more effectively than a human can.

Final Thoughts

The biopharma supply chain can be difficult to get right. The key to mastering this complex web isn’t just in nailing each task associated with the supply chain, but also in building relationships, embracing lean methodologies, and using the insights at your disposal courtesy of advanced analytics.

These strategies we’ve outlined above aren’t just solutions to some of the biopharma supply chain’s biggest obstacles, they also serve as a success story about how far we’ve come in ensuring a healthier world. And, at the end of the day, these strategies are also a reminder that moving forward, every challenge we face is an opportunity to make the recipe even better, to innovate. Every partnership is a chance to push the envelope, and every single data point is a step closer to saving even more lives.